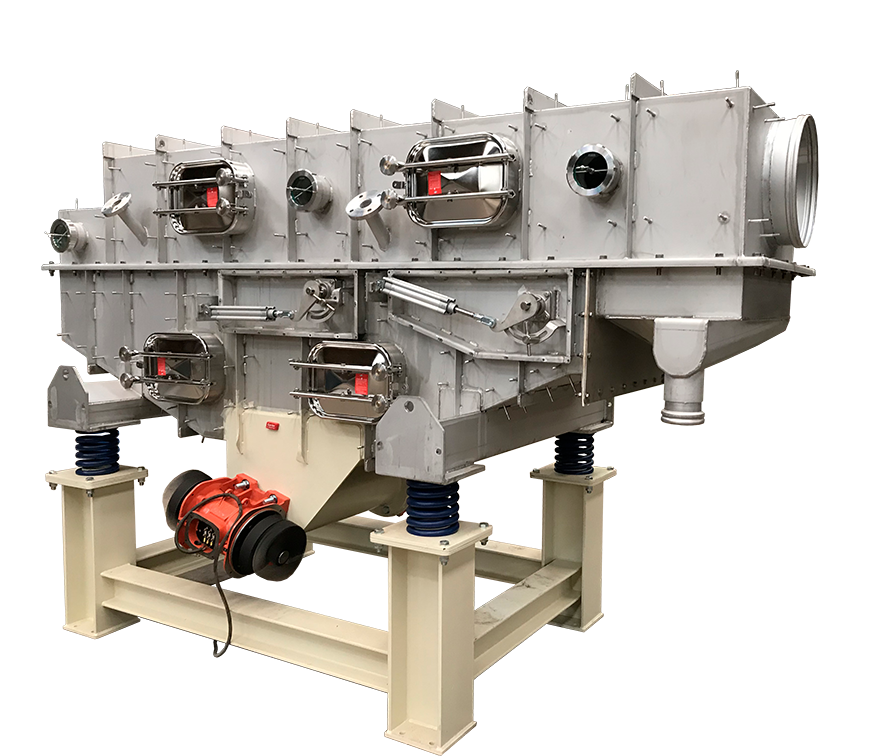

Vibrating Fluid Bed Dryers

Carrier vibrating equipment has been serving various industries worldwide for many decades.

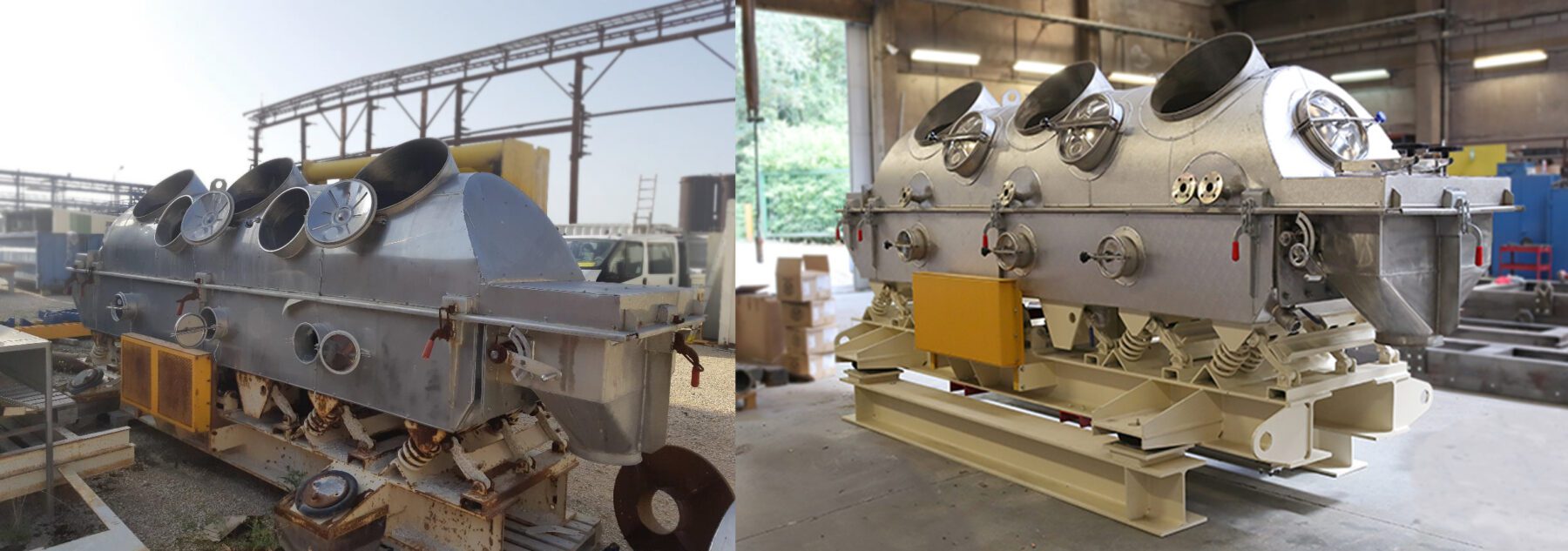

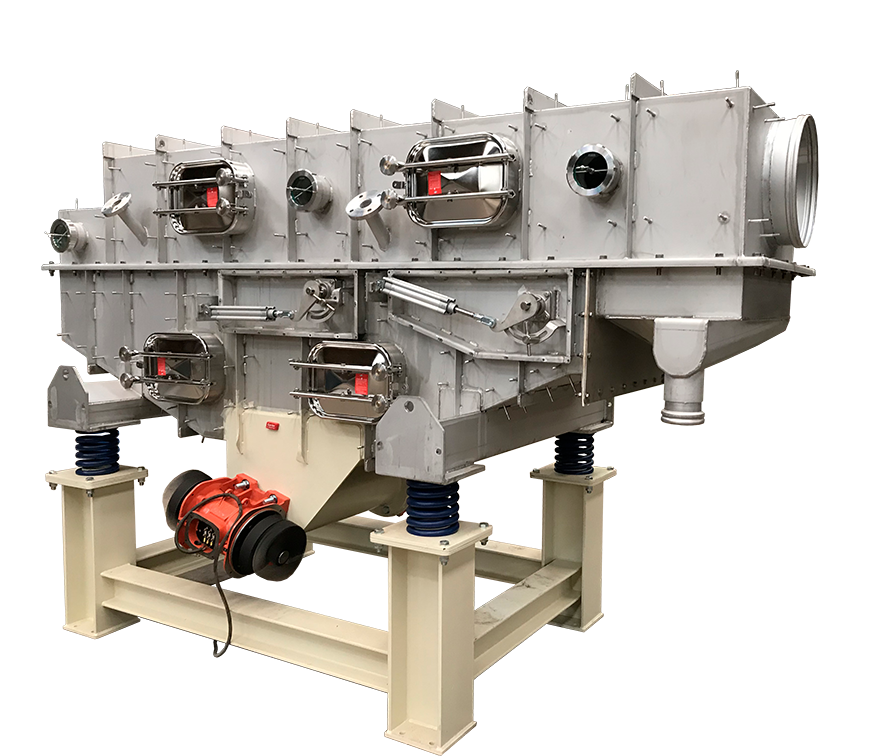

The fluid bed system is known as the most thermally efficient drying method. With a focus on custom design, we gained experience in the processing of a wide variety of products and applications. Our fluid beds dryers are always adapted to your specific needs and requirements.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

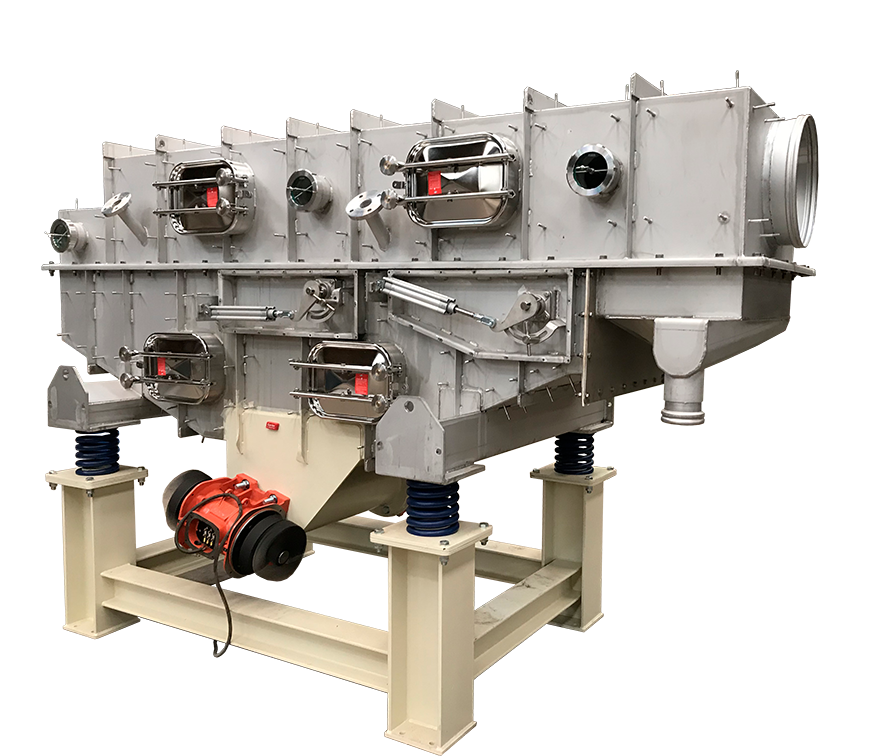

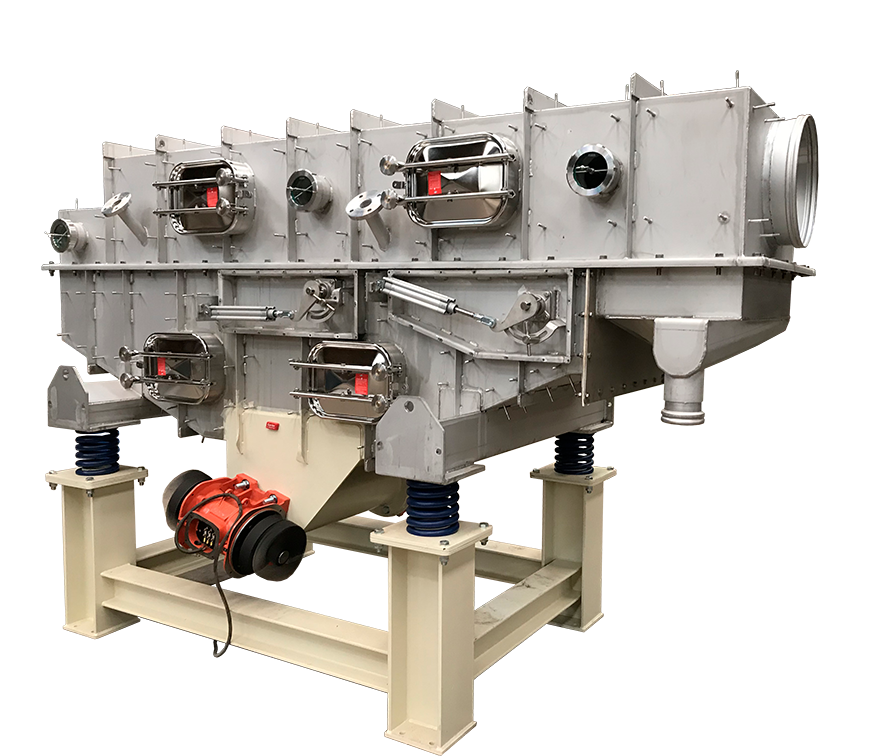

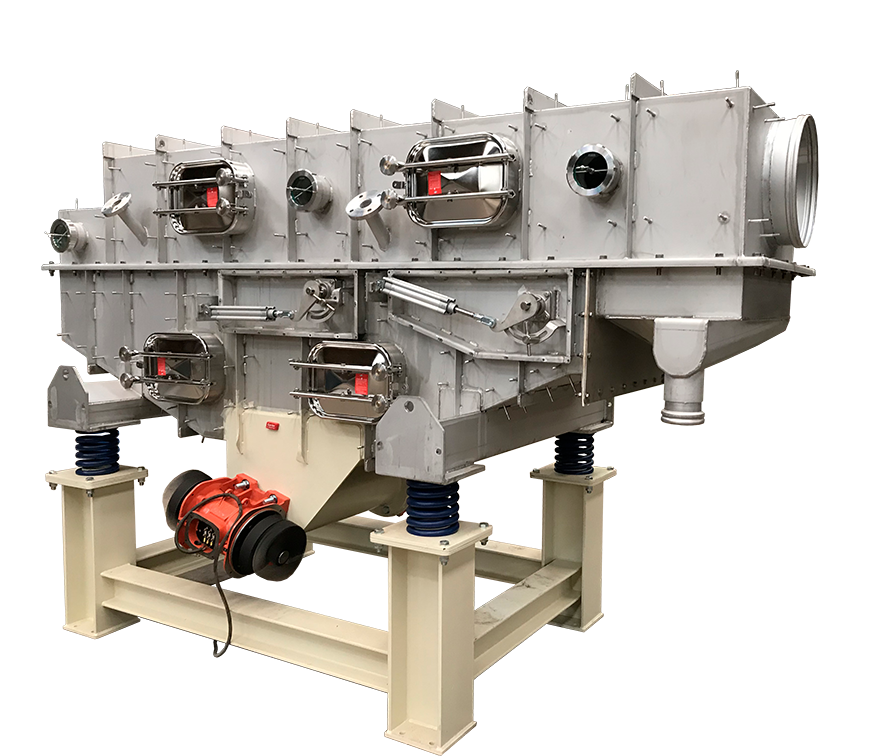

Carrier fluidized bed dryers attain maximum thermal efficiency thanks to the principle of vibration technology. In a fluid bed, the conveying surface is perforated to allow the passage of hot air (in most cases). This hot air surrounds the product particles being repeatedly tossed forward and mixed, so that they are uniformly exposed to it. This allows very effective moisture reduction without risks of burnt areas. Read more about specifically coal drying.

Carrier fluid bed dryers can be used to process many bulk materials like chemicals, pharmaceuticals, plastics, rubber, food, wood, coal, sand, glass cullet, aluminium, and many other mineral, organic or compound products.

Each Carrier bulk material dryer is specially sized for a specific application, after discussions with our customer and product testing in our lab. Each unit can even be equipped with our patented Delta-Phase™ drive system. This quality-of-life tool grants you fully adjustable vibration parameters and total control over retention time to vary finished product conditions. So you can use the same unit for different productions with different drying requirements.

A single Carrier fluid bed unit can also be split into zones to perform successive thermal process like drying, heating, cooling, torrefying, curing,… This not only helps save space in crowded areas of your plant by reducing the number of equipment needed, but also ensures that the outlet product can be immediately conditioned or stored.

On demand, we can provide all the auxiliaries necessary for air supply, exhaust and filtration. We also offer fully recirculated, self-inerting, complete solutions optimized for your process.

Carrier fluid bed dryers can process many bulk solids in many industrial sectors. Are you looking for a custom solution? Let us know!

Vibrating Fluid Bed Dryers

Carrier vibrating equipment has been serving various industries worldwide for many decades.

The fluid bed system is known as the most thermally efficient drying method. With a focus on custom design, we gained experience in the processing of a wide variety of products and applications. Our fluid beds dryers are always adapted to your specific needs and requirements.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier fluidized bed dryers attain maximum thermal efficiency thanks to the principle of vibration technology. In a fluid bed, the conveying surface is perforated to allow the passage of hot air (in most cases). This hot air surrounds the product particles being repeatedly tossed forward and mixed, so that they are uniformly exposed to it. This allows very effective moisture reduction without risks of burnt areas. Read more about specifically coal drying.

Carrier fluid bed dryers can be used to process many bulk materials like chemicals, pharmaceuticals, plastics, rubber, food, wood, coal, sand, glass cullet, aluminium, and many other mineral, organic or compound products.

Each Carrier bulk material dryer is specially sized for a specific application, after discussions with our customer and product testing in our lab. Each unit can even be equipped with our patented Delta-Phase™ drive system. This quality-of-life tool grants you fully adjustable vibration parameters and total control over retention time to vary finished product conditions. So you can use the same unit for different productions with different drying requirements.

A single Carrier fluid bed unit can also be split into zones to perform successive thermal process like drying, heating, cooling, torrefying, curing,… This not only helps save space in crowded areas of your plant by reducing the number of equipment needed, but also ensures that the outlet product can be immediately conditioned or stored.

On demand, we can provide all the auxiliaries necessary for air supply, exhaust and filtration. We also offer fully recirculated, self-inerting, complete solutions optimized for your process.

Carrier fluid bed dryers can process many bulk solids in many industrial sectors. Are you looking for a custom solution? Let us know!

Vibrating Fluid Bed Dryers

Carrier vibrating equipment has been serving various industries worldwide for many decades.

The fluid bed system is known as the most thermally efficient drying method. With a focus on custom design, we gained experience in the processing of a wide variety of products and applications. Our fluid beds dryers are always adapted to your specific needs and requirements.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier fluidized bed dryers attain maximum thermal efficiency thanks to the principle of vibration technology. In a fluid bed, the conveying surface is perforated to allow the passage of hot air (in most cases). This hot air surrounds the product particles being repeatedly tossed forward and mixed, so that they are uniformly exposed to it. This allows very effective moisture reduction without risks of burnt areas. Read more about specifically coal drying.

Carrier fluid bed dryers can be used to process many bulk materials like chemicals, pharmaceuticals, plastics, rubber, food, wood, coal, sand, glass cullet, aluminium, and many other mineral, organic or compound products.

Each Carrier bulk material dryer is specially sized for a specific application, after discussions with our customer and product testing in our lab. Each unit can even be equipped with our patented Delta-Phase™ drive system. This quality-of-life tool grants you fully adjustable vibration parameters and total control over retention time to vary finished product conditions. So you can use the same unit for different productions with different drying requirements.

A single Carrier fluid bed unit can also be split into zones to perform successive thermal process like drying, heating, cooling, torrefying, curing,… This not only helps save space in crowded areas of your plant by reducing the number of equipment needed, but also ensures that the outlet product can be immediately conditioned or stored.

On demand, we can provide all the auxiliaries necessary for air supply, exhaust and filtration. We also offer fully recirculated, self-inerting, complete solutions optimized for your process.

Carrier fluid bed dryers can process many bulk solids in many industrial sectors. Are you looking for a custom solution? Let us know!

Vibrating Fluid Bed Dryers

Carrier vibrating equipment has been serving various industries worldwide for many decades.

The fluid bed system is known as the most thermally efficient drying method. With a focus on custom design, we gained experience in the processing of a wide variety of products and applications. Our fluid beds dryers are always adapted to your specific needs and requirements.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier fluidized bed dryers attain maximum thermal efficiency thanks to the principle of vibration technology. In a fluid bed, the conveying surface is perforated to allow the passage of hot air (in most cases). This hot air surrounds the product particles being repeatedly tossed forward and mixed, so that they are uniformly exposed to it. This allows very effective moisture reduction without risks of burnt areas. Read more about specifically coal drying.

Carrier fluid bed dryers can be used to process many bulk materials like chemicals, pharmaceuticals, plastics, rubber, food, wood, coal, sand, glass cullet, aluminium, and many other mineral, organic or compound products.

Each Carrier bulk material dryer is specially sized for a specific application, after discussions with our customer and product testing in our lab. Each unit can even be equipped with our patented Delta-Phase™ drive system. This quality-of-life tool grants you fully adjustable vibration parameters and total control over retention time to vary finished product conditions. So you can use the same unit for different productions with different drying requirements.

A single Carrier fluid bed unit can also be split into zones to perform successive thermal process like drying, heating, cooling, torrefying, curing,… This not only helps save space in crowded areas of your plant by reducing the number of equipment needed, but also ensures that the outlet product can be immediately conditioned or stored.

On demand, we can provide all the auxiliaries necessary for air supply, exhaust and filtration. We also offer fully recirculated, self-inerting, complete solutions optimized for your process.

Carrier fluid bed dryers can process many bulk solids in many industrial sectors. Are you looking for a custom solution? Let us know!

Vibrating Fluid Bed Dryers

Carrier vibrating equipment has been serving various industries worldwide for many decades.

The fluid bed system is known as the most thermally efficient drying method. With a focus on custom design, we gained experience in the processing of a wide variety of products and applications. Our fluid beds dryers are always adapted to your specific needs and requirements.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier fluidized bed dryers attain maximum thermal efficiency thanks to the principle of vibration technology. In a fluid bed, the conveying surface is perforated to allow the passage of hot air (in most cases). This hot air surrounds the product particles being repeatedly tossed forward and mixed, so that they are uniformly exposed to it. This allows very effective moisture reduction without risks of burnt areas. Read more about specifically coal drying.

Carrier fluid bed dryers can be used to process many bulk materials like chemicals, pharmaceuticals, plastics, rubber, food, wood, coal, sand, glass cullet, aluminium, and many other mineral, organic or compound products.

Each Carrier bulk material dryer is specially sized for a specific application, after discussions with our customer and product testing in our lab. Each unit can even be equipped with our patented Delta-Phase™ drive system. This quality-of-life tool grants you fully adjustable vibration parameters and total control over retention time to vary finished product conditions. So you can use the same unit for different productions with different drying requirements.

A single Carrier fluid bed unit can also be split into zones to perform successive thermal process like drying, heating, cooling, torrefying, curing,… This not only helps save space in crowded areas of your plant by reducing the number of equipment needed, but also ensures that the outlet product can be immediately conditioned or stored.

On demand, we can provide all the auxiliaries necessary for air supply, exhaust and filtration. We also offer fully recirculated, self-inerting, complete solutions optimized for your process.

Carrier fluid bed dryers can process many bulk solids in many industrial sectors. Are you looking for a custom solution? Let us know!

Vibrating Fluid Bed Dryers

Carrier vibrating equipment has been serving various industries worldwide for many decades.

The fluid bed system is known as the most thermally efficient drying method. With a focus on custom design, we gained experience in the processing of a wide variety of products and applications. Our fluid beds dryers are always adapted to your specific needs and requirements.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier fluidized bed dryers attain maximum thermal efficiency thanks to the principle of vibration technology. In a fluid bed, the conveying surface is perforated to allow the passage of hot air (in most cases). This hot air surrounds the product particles being repeatedly tossed forward and mixed, so that they are uniformly exposed to it. This allows very effective moisture reduction without risks of burnt areas. Read more about specifically coal drying.

Carrier fluid bed dryers can be used to process many bulk materials like chemicals, pharmaceuticals, plastics, rubber, food, wood, coal, sand, glass cullet, aluminium, and many other mineral, organic or compound products.

Each Carrier bulk material dryer is specially sized for a specific application, after discussions with our customer and product testing in our lab. Each unit can even be equipped with our patented Delta-Phase™ drive system. This quality-of-life tool grants you fully adjustable vibration parameters and total control over retention time to vary finished product conditions. So you can use the same unit for different productions with different drying requirements.

A single Carrier fluid bed unit can also be split into zones to perform successive thermal process like drying, heating, cooling, torrefying, curing,… This not only helps save space in crowded areas of your plant by reducing the number of equipment needed, but also ensures that the outlet product can be immediately conditioned or stored.

On demand, we can provide all the auxiliaries necessary for air supply, exhaust and filtration. We also offer fully recirculated, self-inerting, complete solutions optimized for your process.

Carrier fluid bed dryers can process many bulk solids in many industrial sectors. Are you looking for a custom solution? Let us know!

Vibrating Fluid Bed Dryers

Carrier vibrating equipment has been serving various industries worldwide for many decades.

The fluid bed system is known as the most thermally efficient drying method. With a focus on custom design, we gained experience in the processing of a wide variety of products and applications. Our fluid beds dryers are always adapted to your specific needs and requirements.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier fluidized bed dryers attain maximum thermal efficiency thanks to the principle of vibration technology. In a fluid bed, the conveying surface is perforated to allow the passage of hot air (in most cases). This hot air surrounds the product particles being repeatedly tossed forward and mixed, so that they are uniformly exposed to it. This allows very effective moisture reduction without risks of burnt areas. Read more about specifically coal drying.

Carrier fluid bed dryers can be used to process many bulk materials like chemicals, pharmaceuticals, plastics, rubber, food, wood, coal, sand, glass cullet, aluminium, and many other mineral, organic or compound products.

Each Carrier bulk material dryer is specially sized for a specific application, after discussions with our customer and product testing in our lab. Each unit can even be equipped with our patented Delta-Phase™ drive system. This quality-of-life tool grants you fully adjustable vibration parameters and total control over retention time to vary finished product conditions. So you can use the same unit for different productions with different drying requirements.

A single Carrier fluid bed unit can also be split into zones to perform successive thermal process like drying, heating, cooling, torrefying, curing,… This not only helps save space in crowded areas of your plant by reducing the number of equipment needed, but also ensures that the outlet product can be immediately conditioned or stored.

On demand, we can provide all the auxiliaries necessary for air supply, exhaust and filtration. We also offer fully recirculated, self-inerting, complete solutions optimized for your process.

Carrier fluid bed dryers can process many bulk solids in many industrial sectors. Are you looking for a custom solution? Let us know!

Vibrating Fluid Bed Dryers

Carrier vibrating equipment has been serving various industries worldwide for many decades.

The fluid bed system is known as the most thermally efficient drying method. With a focus on custom design, we gained experience in the processing of a wide variety of products and applications. Our fluid beds dryers are always adapted to your specific needs and requirements.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier fluidized bed dryers attain maximum thermal efficiency thanks to the principle of vibration technology. In a fluid bed, the conveying surface is perforated to allow the passage of hot air (in most cases). This hot air surrounds the product particles being repeatedly tossed forward and mixed, so that they are uniformly exposed to it. This allows very effective moisture reduction without risks of burnt areas. Read more about specifically coal drying.

Carrier fluid bed dryers can be used to process many bulk materials like chemicals, pharmaceuticals, plastics, rubber, food, wood, coal, sand, glass cullet, aluminium, and many other mineral, organic or compound products.

Each Carrier bulk material dryer is specially sized for a specific application, after discussions with our customer and product testing in our lab. Each unit can even be equipped with our patented Delta-Phase™ drive system. This quality-of-life tool grants you fully adjustable vibration parameters and total control over retention time to vary finished product conditions. So you can use the same unit for different productions with different drying requirements.

A single Carrier fluid bed unit can also be split into zones to perform successive thermal process like drying, heating, cooling, torrefying, curing,… This not only helps save space in crowded areas of your plant by reducing the number of equipment needed, but also ensures that the outlet product can be immediately conditioned or stored.

On demand, we can provide all the auxiliaries necessary for air supply, exhaust and filtration. We also offer fully recirculated, self-inerting, complete solutions optimized for your process.

Carrier fluid bed dryers can process many bulk solids in many industrial sectors. Are you looking for a custom solution? Let us know!

A CUSTOM SOLUTION?