Why you should cool off plastic pellets

As one of the most widely used products in the world, Polyvinyl Chloride (or PVC) has been the target of many sustainable development actions for the last decades, with more than 770 000 tons recycled in Europe in 2019, and a goal set to 900 000 tons per year until 2025.

During the recycling process, PVC is purified and dried, then sliced and compressed as pellets for storing until it begins a new life. At this point, residual heat resulting from the drying phase may cause the pellets to auto-consume and agglomerate. While the smoke from consumption is obviously a primary concern, another problem is that lumps of plastics cannot be poured out of the storing silo for re-use.

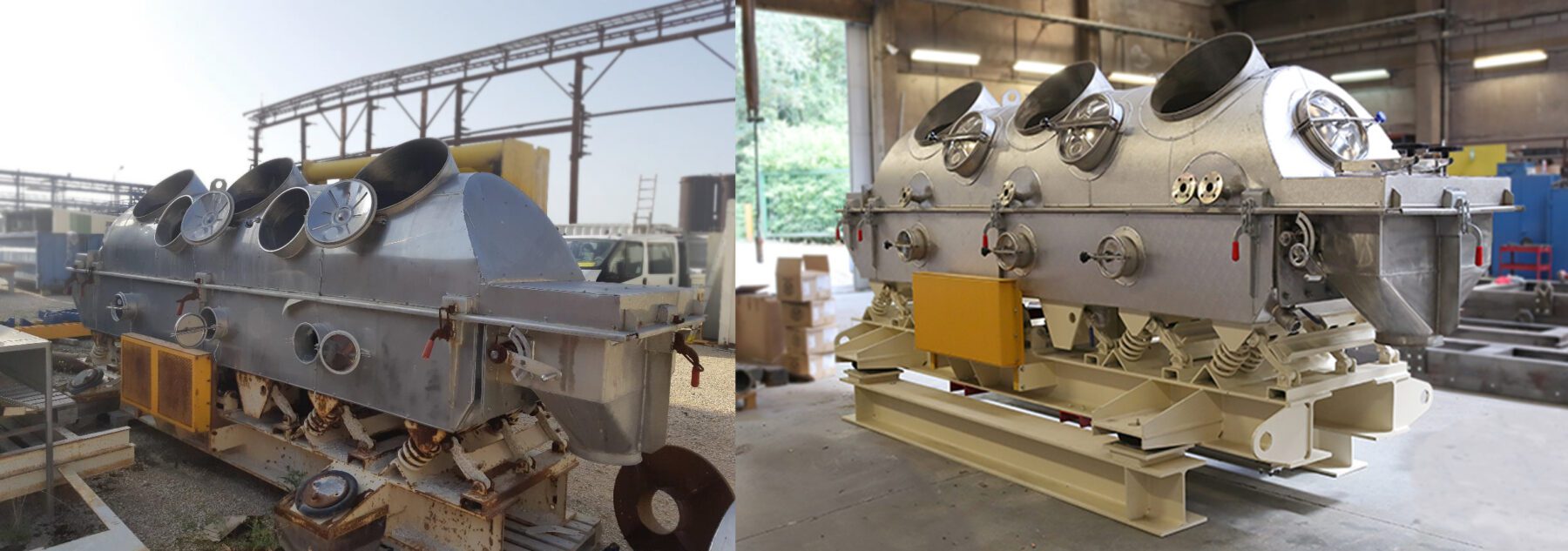

Searching for a solution to this, a recycling company approached us via an integrator. A reference visit was organized in a plant equipped with one of our fluid bed (FB) coolers for carbon powder. The recycling company was not familiar with vibrating technology. The simple and compact solution got their attention and soon tests in our lab with samples of their product were organized on a batch FB cooler.

After extrapolation of the results, we guaranteed a temperature reduction of the PVC pellets from 100°C to 30°C at a capacity rate of 1,2T/h using a FB design of less than 4m long.

The unit was installed and started without problem and immediately produced a strong impression on the customer staff, who were not used to vibrating equipment. They since have grown accustomed to play with angle of attack, stroke and other settings.

For almost two years now, the FB has been running smoothly 24/7 with very few monitoring and maintenance downtime. Being the most reliable piece of equipment on the entire production line, even compared to other – more recently installed – vibrating equipment from the competition, the customer can agree that Carrier Europe lives up to its reputation of providing robust and low maintenance solutions!