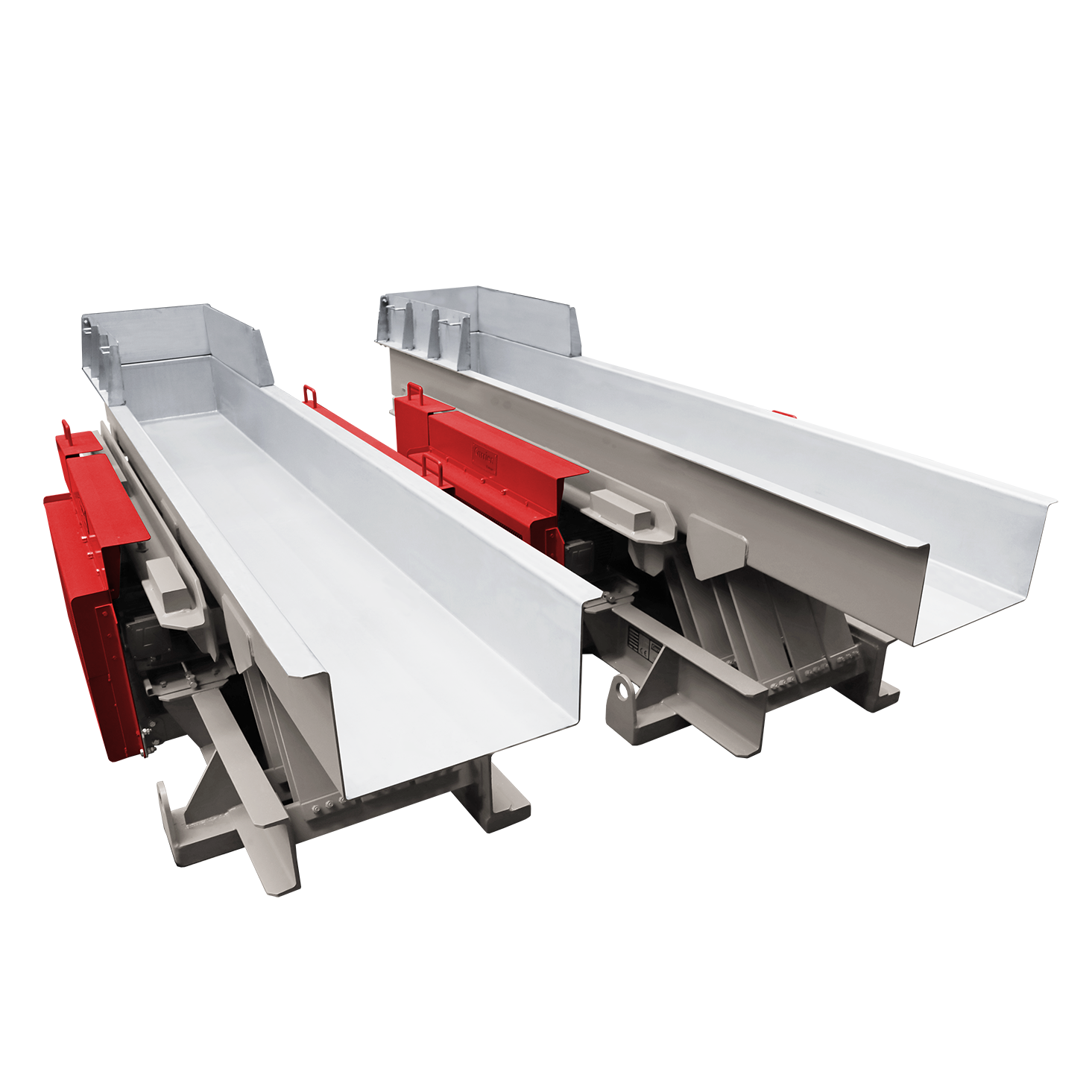

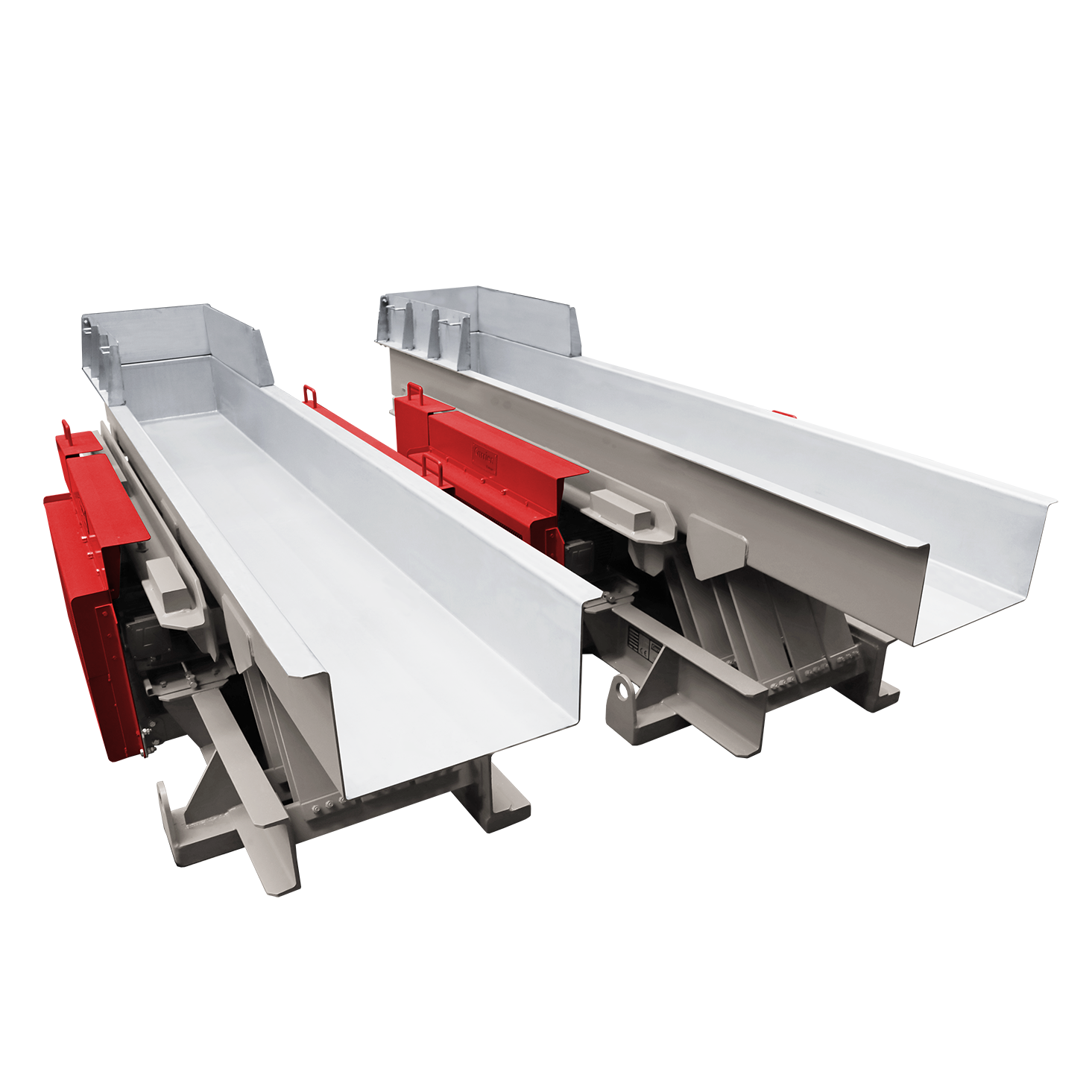

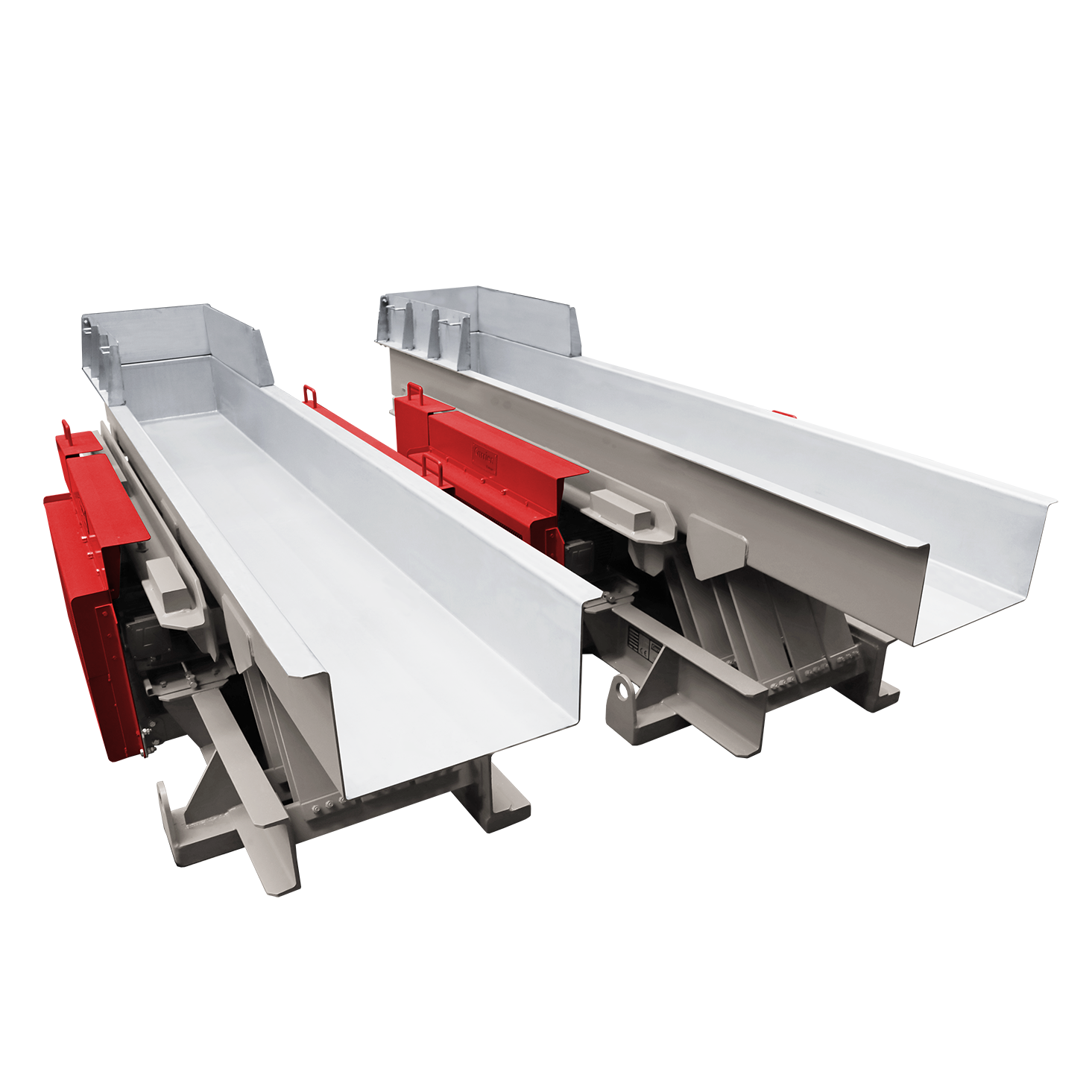

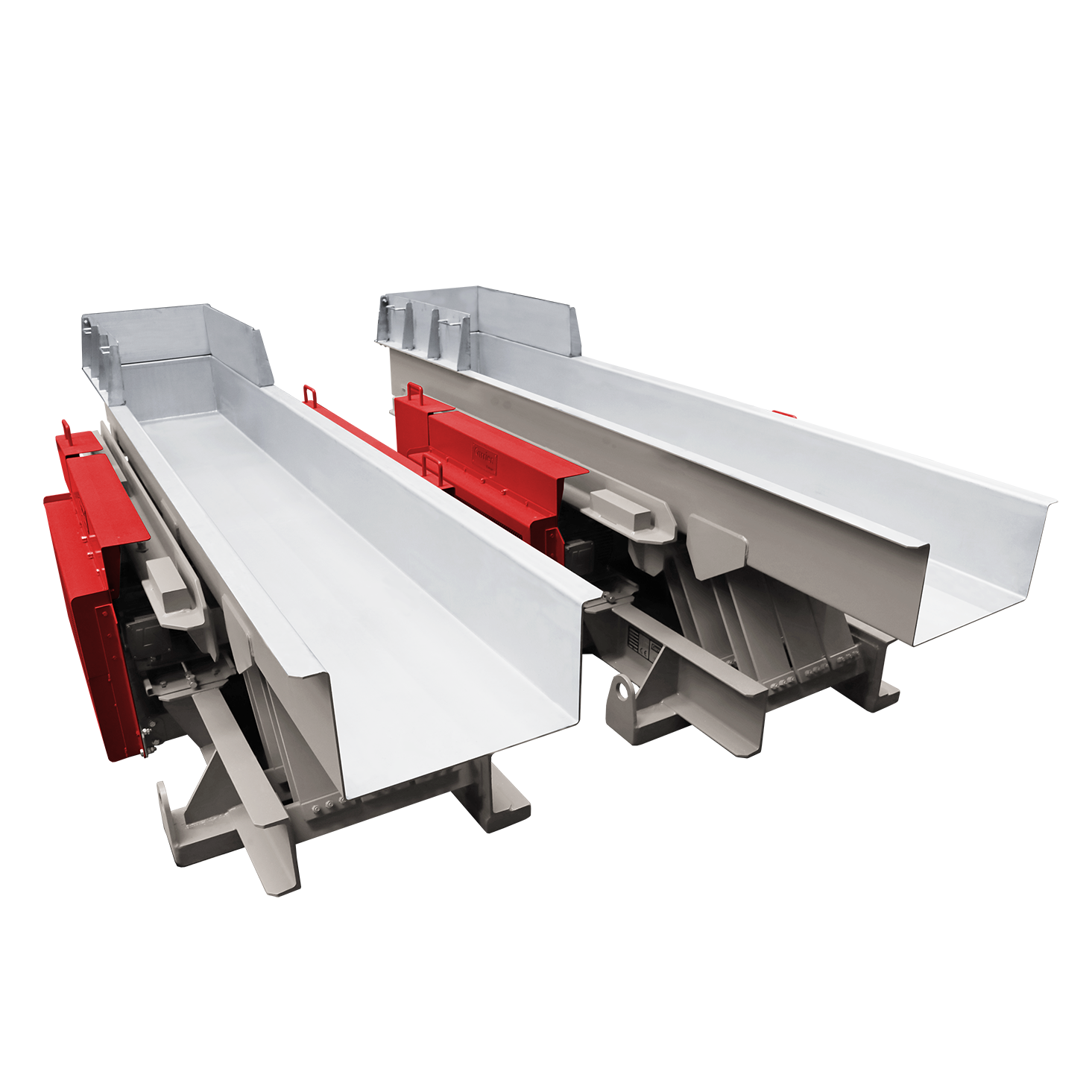

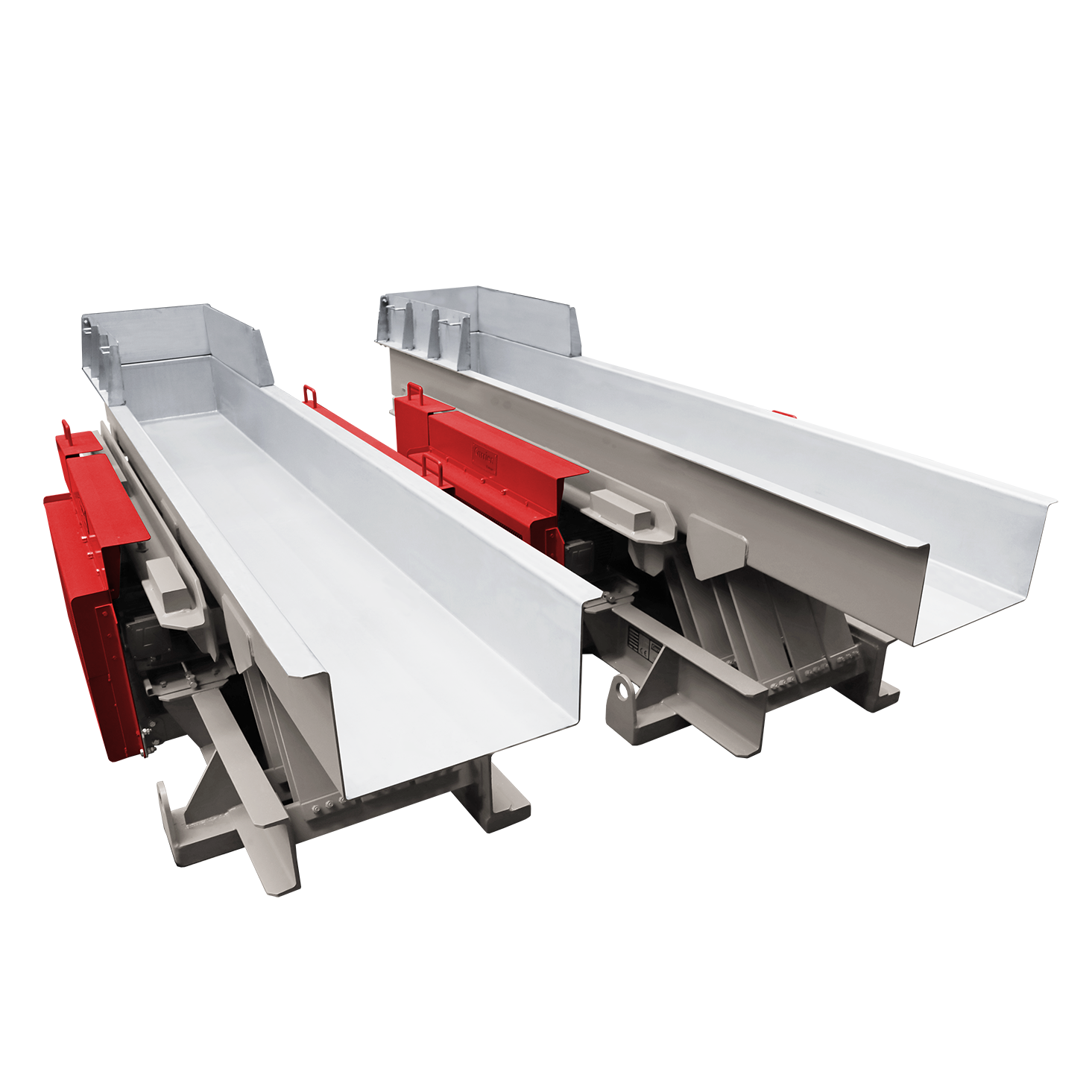

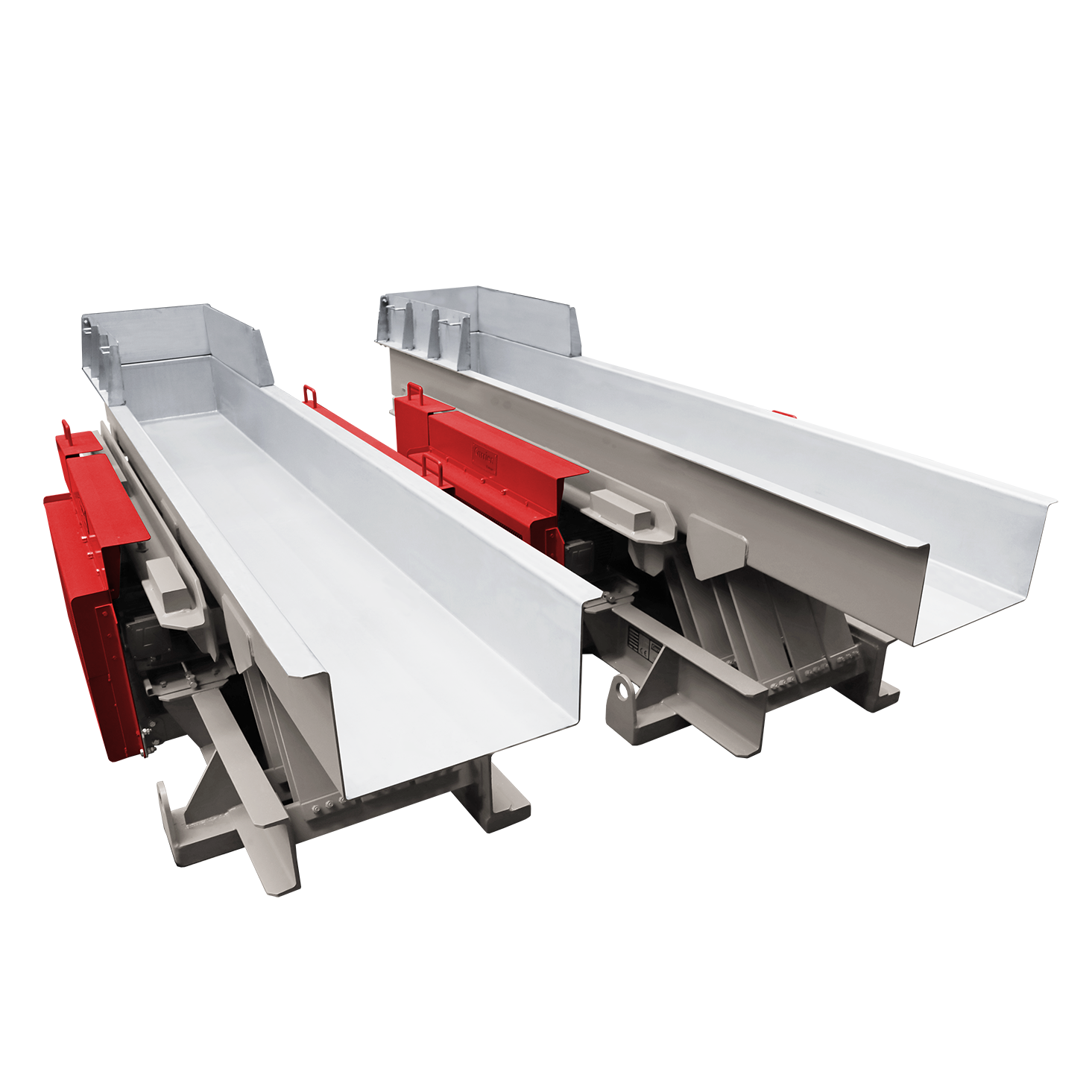

Vibrating Feeders

For many decades, Carrier has been providing the most robust and reliable vibrating processing machines for many industries.

Vibrating feeders ensure a constant and controlled feeding rate from delicate dosage to large flow. They are designed to comply to your specific needs and constraints, and to guarantee the best profitability of your production lines.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Heavy-duty design fit for many environments

Our equipment is renowned for its robust and heavy-duty design. It is very well suited for large capacities, severe environment and high temperature, like in foundries to charge a furnace or for mold dumping. Large size units can also be placed in woodyards, and units with abrasion-resistant trough surface find a spot in recycling and waste management plants. Its reliability highly reduces downtime and maximizes production throughput.

Pinpoint precision to accommodate to your desired flow

Vibrating feeders are tuned to your specific needs by our experienced engineers to provide a regular and uniform discharge flow. They can be used in industries where the greatest accuracy is mandatory, like for the balers in synthetic rubber plants. We also propose adjustable feed rate systems and weigh cells to fully control your feeding rate.

Feeders can also perform other tasks

Like all our solutions, vibrating feeders can be equipped to complete other process:

- Drying/preheating

- Dewatering

- Screening, scalping, sorting,…

Carrier vibrating feeders are the right solution for many applications and many materials. Do not hesitate to contact us to learn more about this equipment, and about how we manage its whole lifetime with customer service.

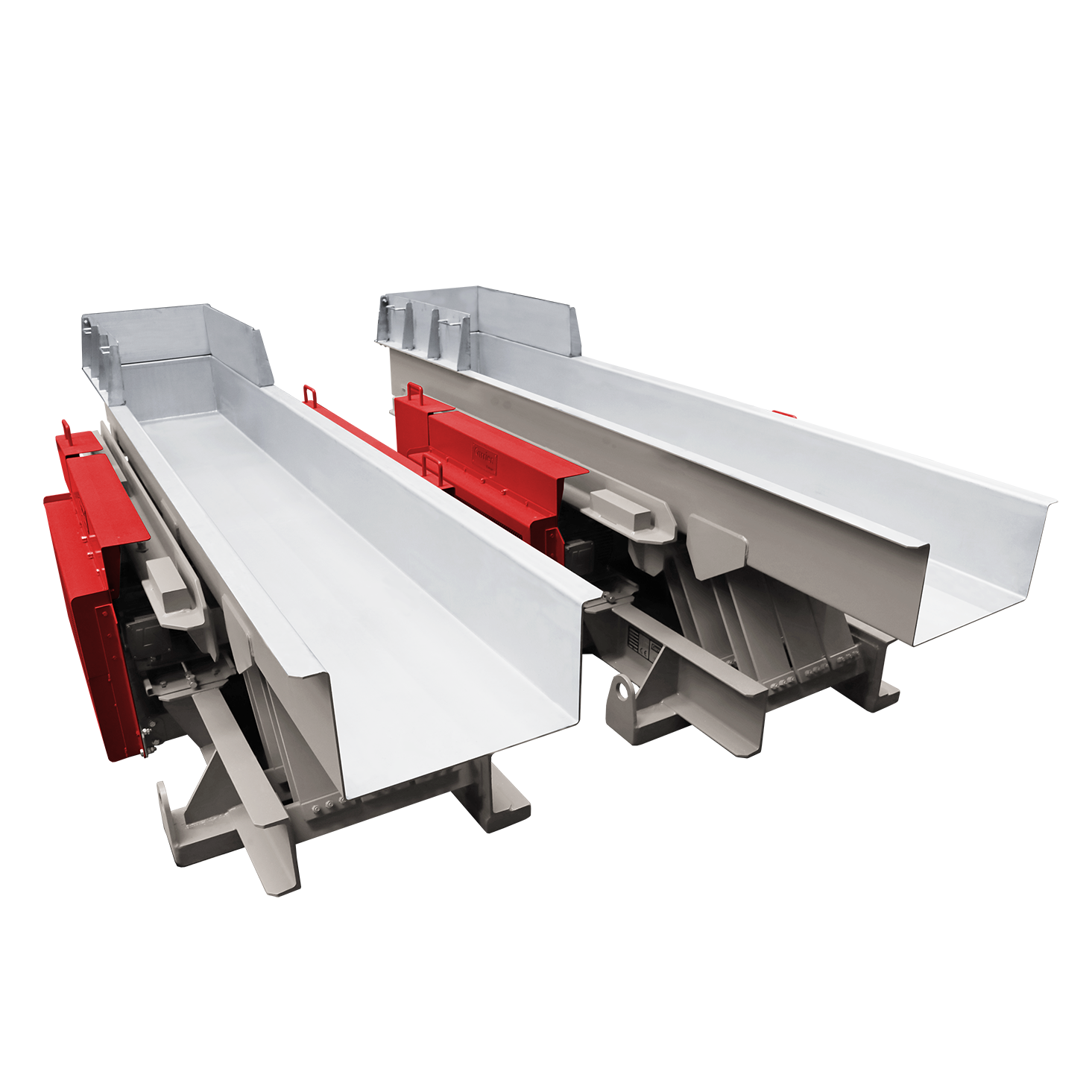

Vibrating Feeders

For many decades, Carrier has been providing the most robust and reliable vibrating processing machines for many industries.

Vibrating feeders ensure a constant and controlled feeding rate from delicate dosage to large flow. They are designed to comply to your specific needs and constraints, and to guarantee the best profitability of your production lines.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Heavy-duty design fit for many environments

Our equipment is renowned for its robust and heavy-duty design. It is very well suited for large capacities, severe environment and high temperature, like in foundries to charge a furnace or for mold dumping. Large size units can also be placed in woodyards, and units with abrasion-resistant trough surface find a spot in recycling and waste management plants. Its reliability highly reduces downtime and maximizes production throughput.

Pinpoint precision to accommodate to your desired flow

Vibrating feeders are tuned to your specific needs by our experienced engineers to provide a regular and uniform discharge flow. They can be used in industries where the greatest accuracy is mandatory, like for the balers in synthetic rubber plants. We also propose adjustable feed rate systems and weigh cells to fully control your feeding rate.

Feeders can also perform other tasks

Like all our solutions, vibrating feeders can be equipped to complete other process:

- Drying/preheating

- Dewatering

- Screening, scalping, sorting,…

Carrier vibrating feeders are the right solution for many applications and many materials. Do not hesitate to contact us to learn more about this equipment, and about how we manage its whole lifetime with customer service.

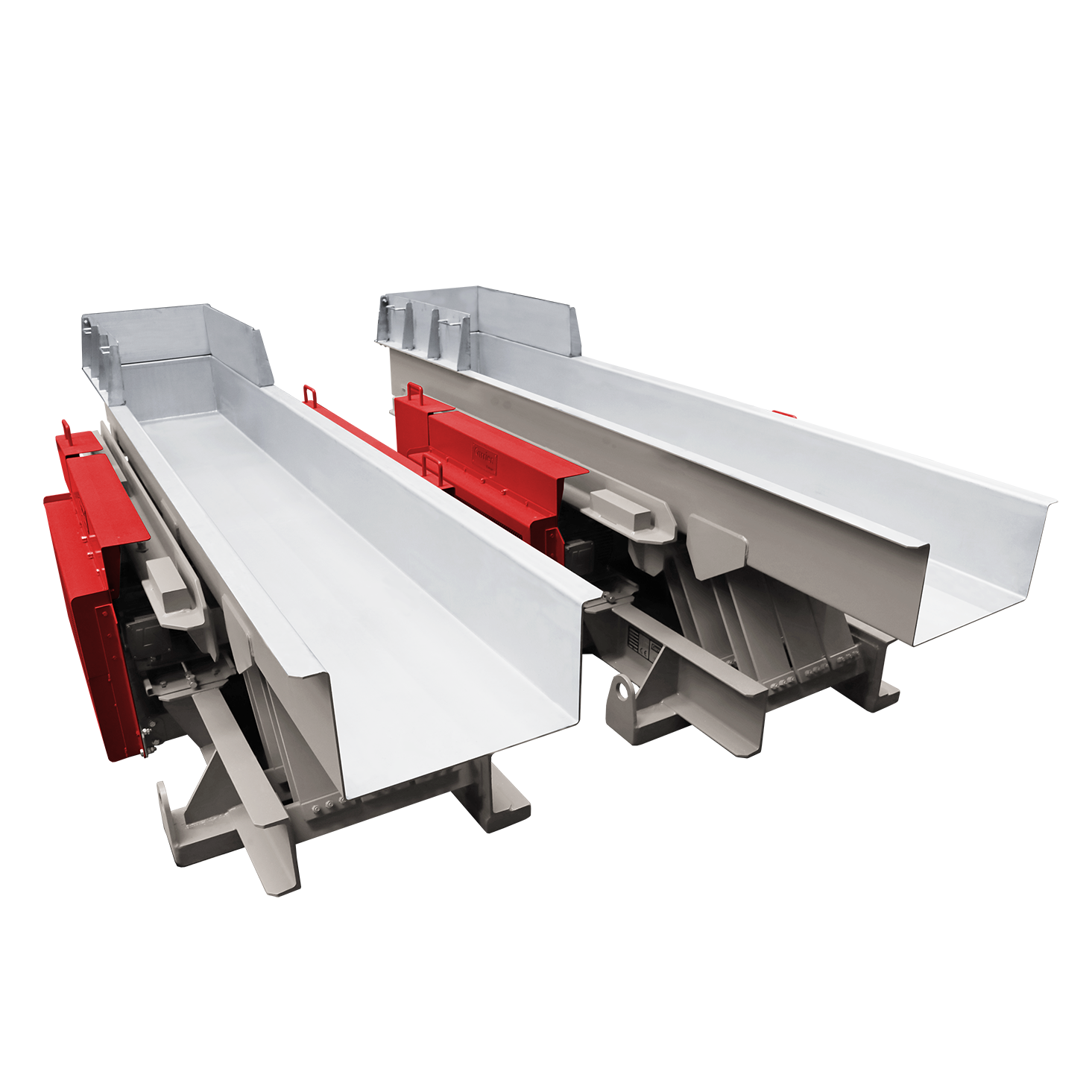

Vibrating Feeders

For many decades, Carrier has been providing the most robust and reliable vibrating processing machines for many industries.

Vibrating feeders ensure a constant and controlled feeding rate from delicate dosage to large flow. They are designed to comply to your specific needs and constraints, and to guarantee the best profitability of your production lines.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Heavy-duty design fit for many environments

Our equipment is renowned for its robust and heavy-duty design. It is very well suited for large capacities, severe environment and high temperature, like in foundries to charge a furnace or for mold dumping. Large size units can also be placed in woodyards, and units with abrasion-resistant trough surface find a spot in recycling and waste management plants. Its reliability highly reduces downtime and maximizes production throughput.

Pinpoint precision to accommodate to your desired flow

Vibrating feeders are tuned to your specific needs by our experienced engineers to provide a regular and uniform discharge flow. They can be used in industries where the greatest accuracy is mandatory, like for the balers in synthetic rubber plants. We also propose adjustable feed rate systems and weigh cells to fully control your feeding rate.

Feeders can also perform other tasks

Like all our solutions, vibrating feeders can be equipped to complete other process:

- Drying/preheating

- Dewatering

- Screening, scalping, sorting,…

Carrier vibrating feeders are the right solution for many applications and many materials. Do not hesitate to contact us to learn more about this equipment, and about how we manage its whole lifetime with customer service.

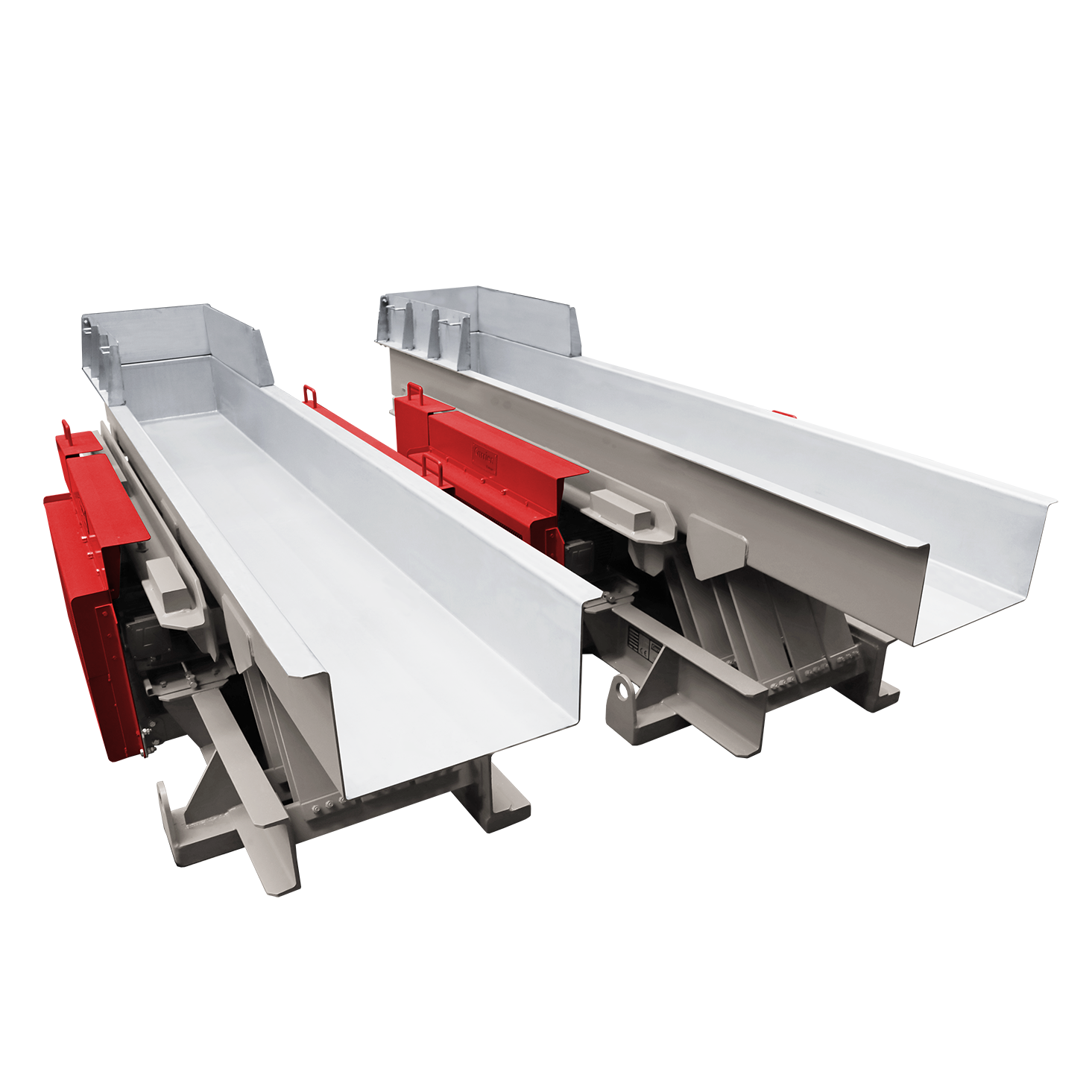

Vibrating Feeders

For many decades, Carrier has been providing the most robust and reliable vibrating processing machines for many industries.

Vibrating feeders ensure a constant and controlled feeding rate from delicate dosage to large flow. They are designed to comply to your specific needs and constraints, and to guarantee the best profitability of your production lines.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Heavy-duty design fit for many environments

Our equipment is renowned for its robust and heavy-duty design. It is very well suited for large capacities, severe environment and high temperature, like in foundries to charge a furnace or for mold dumping. Large size units can also be placed in woodyards, and units with abrasion-resistant trough surface find a spot in recycling and waste management plants. Its reliability highly reduces downtime and maximizes production throughput.

Pinpoint precision to accommodate to your desired flow

Vibrating feeders are tuned to your specific needs by our experienced engineers to provide a regular and uniform discharge flow. They can be used in industries where the greatest accuracy is mandatory, like for the balers in synthetic rubber plants. We also propose adjustable feed rate systems and weigh cells to fully control your feeding rate.

Feeders can also perform other tasks

Like all our solutions, vibrating feeders can be equipped to complete other process:

- Drying/preheating

- Dewatering

- Screening, scalping, sorting,…

Carrier vibrating feeders are the right solution for many applications and many materials. Do not hesitate to contact us to learn more about this equipment, and about how we manage its whole lifetime with customer service.

Vibrating Feeders

For many decades, Carrier has been providing the most robust and reliable vibrating processing machines for many industries.

Vibrating feeders ensure a constant and controlled feeding rate from delicate dosage to large flow. They are designed to comply to your specific needs and constraints, and to guarantee the best profitability of your production lines.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Heavy-duty design fit for many environments

Our equipment is renowned for its robust and heavy-duty design. It is very well suited for large capacities, severe environment and high temperature, like in foundries to charge a furnace or for mold dumping. Large size units can also be placed in woodyards, and units with abrasion-resistant trough surface find a spot in recycling and waste management plants. Its reliability highly reduces downtime and maximizes production throughput.

Pinpoint precision to accommodate to your desired flow

Vibrating feeders are tuned to your specific needs by our experienced engineers to provide a regular and uniform discharge flow. They can be used in industries where the greatest accuracy is mandatory, like for the balers in synthetic rubber plants. We also propose adjustable feed rate systems and weigh cells to fully control your feeding rate.

Feeders can also perform other tasks

Like all our solutions, vibrating feeders can be equipped to complete other process:

- Drying/preheating

- Dewatering

- Screening, scalping, sorting,…

Carrier vibrating feeders are the right solution for many applications and many materials. Do not hesitate to contact us to learn more about this equipment, and about how we manage its whole lifetime with customer service.

Vibrating Feeders

For many decades, Carrier has been providing the most robust and reliable vibrating processing machines for many industries.

Vibrating feeders ensure a constant and controlled feeding rate from delicate dosage to large flow. They are designed to comply to your specific needs and constraints, and to guarantee the best profitability of your production lines.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Heavy-duty design fit for many environments

Our equipment is renowned for its robust and heavy-duty design. It is very well suited for large capacities, severe environment and high temperature, like in foundries to charge a furnace or for mold dumping. Large size units can also be placed in woodyards, and units with abrasion-resistant trough surface find a spot in recycling and waste management plants. Its reliability highly reduces downtime and maximizes production throughput.

Pinpoint precision to accommodate to your desired flow

Vibrating feeders are tuned to your specific needs by our experienced engineers to provide a regular and uniform discharge flow. They can be used in industries where the greatest accuracy is mandatory, like for the balers in synthetic rubber plants. We also propose adjustable feed rate systems and weigh cells to fully control your feeding rate.

Feeders can also perform other tasks

Like all our solutions, vibrating feeders can be equipped to complete other process:

- Drying/preheating

- Dewatering

- Screening, scalping, sorting,…

Carrier vibrating feeders are the right solution for many applications and many materials. Do not hesitate to contact us to learn more about this equipment, and about how we manage its whole lifetime with customer service.

Vibrating Feeders

For many decades, Carrier has been providing the most robust and reliable vibrating processing machines for many industries.

Vibrating feeders ensure a constant and controlled feeding rate from delicate dosage to large flow. They are designed to comply to your specific needs and constraints, and to guarantee the best profitability of your production lines.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Heavy-duty design fit for many environments

Our equipment is renowned for its robust and heavy-duty design. It is very well suited for large capacities, severe environment and high temperature, like in foundries to charge a furnace or for mold dumping. Large size units can also be placed in woodyards, and units with abrasion-resistant trough surface find a spot in recycling and waste management plants. Its reliability highly reduces downtime and maximizes production throughput.

Pinpoint precision to accommodate to your desired flow

Vibrating feeders are tuned to your specific needs by our experienced engineers to provide a regular and uniform discharge flow. They can be used in industries where the greatest accuracy is mandatory, like for the balers in synthetic rubber plants. We also propose adjustable feed rate systems and weigh cells to fully control your feeding rate.

Feeders can also perform other tasks

Like all our solutions, vibrating feeders can be equipped to complete other process:

- Drying/preheating

- Dewatering

- Screening, scalping, sorting,…

Carrier vibrating feeders are the right solution for many applications and many materials. Do not hesitate to contact us to learn more about this equipment, and about how we manage its whole lifetime with customer service.

Vibrating Feeders

For many decades, Carrier has been providing the most robust and reliable vibrating processing machines for many industries.

Vibrating feeders ensure a constant and controlled feeding rate from delicate dosage to large flow. They are designed to comply to your specific needs and constraints, and to guarantee the best profitability of your production lines.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Heavy-duty design fit for many environments

Our equipment is renowned for its robust and heavy-duty design. It is very well suited for large capacities, severe environment and high temperature, like in foundries to charge a furnace or for mold dumping. Large size units can also be placed in woodyards, and units with abrasion-resistant trough surface find a spot in recycling and waste management plants. Its reliability highly reduces downtime and maximizes production throughput.

Pinpoint precision to accommodate to your desired flow

Vibrating feeders are tuned to your specific needs by our experienced engineers to provide a regular and uniform discharge flow. They can be used in industries where the greatest accuracy is mandatory, like for the balers in synthetic rubber plants. We also propose adjustable feed rate systems and weigh cells to fully control your feeding rate.

Feeders can also perform other tasks

Like all our solutions, vibrating feeders can be equipped to complete other process:

- Drying/preheating

- Dewatering

- Screening, scalping, sorting,…

Carrier vibrating feeders are the right solution for many applications and many materials. Do not hesitate to contact us to learn more about this equipment, and about how we manage its whole lifetime with customer service.

Vibrating Feeders

For many decades, Carrier has been providing the most robust and reliable vibrating processing machines for many industries.

Vibrating feeders ensure a constant and controlled feeding rate from delicate dosage to large flow. They are designed to comply to your specific needs and constraints, and to guarantee the best profitability of your production lines.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Heavy-duty design fit for many environments

Our equipment is renowned for its robust and heavy-duty design. It is very well suited for large capacities, severe environment and high temperature, like in foundries to charge a furnace or for mold dumping. Large size units can also be placed in woodyards, and units with abrasion-resistant trough surface find a spot in recycling and waste management plants. Its reliability highly reduces downtime and maximizes production throughput.

Pinpoint precision to accommodate to your desired flow

Vibrating feeders are tuned to your specific needs by our experienced engineers to provide a regular and uniform discharge flow. They can be used in industries where the greatest accuracy is mandatory, like for the balers in synthetic rubber plants. We also propose adjustable feed rate systems and weigh cells to fully control your feeding rate.

Feeders can also perform other tasks

Like all our solutions, vibrating feeders can be equipped to complete other process:

- Drying/preheating

- Dewatering

- Screening, scalping, sorting,…

Carrier vibrating feeders are the right solution for many applications and many materials. Do not hesitate to contact us to learn more about this equipment, and about how we manage its whole lifetime with customer service.

A CUSTOM SOLUTION?