Vibrating Conveyors

Carrier is the reference in custom design and manufacturing of vibrating equipment for bulk material processing.

Our vibrating conveyors operate on natural frequency. They are the most reliable and energy-saving system to simultaneously convey and process solids, powders and other bulk products from every industry.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

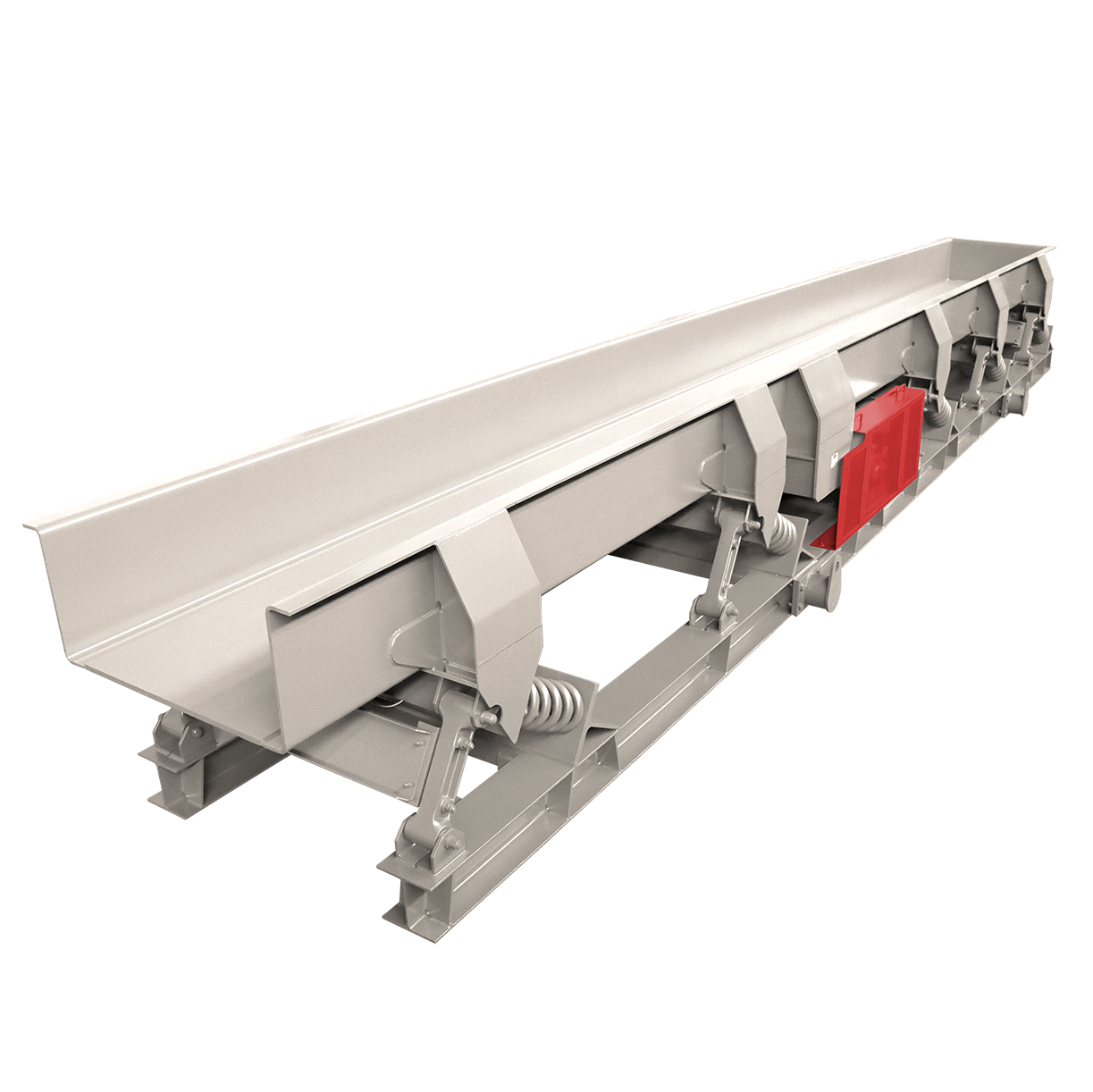

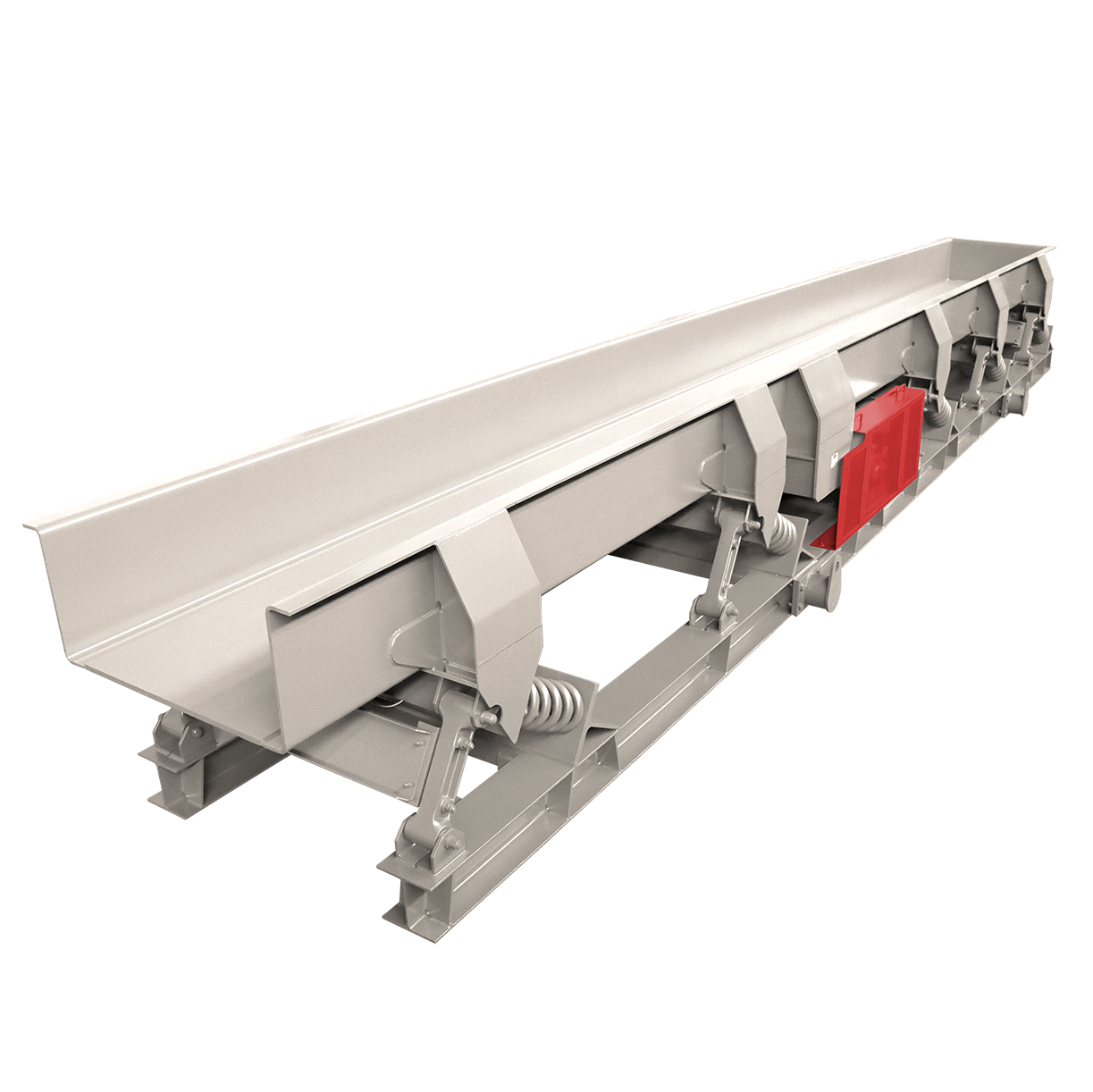

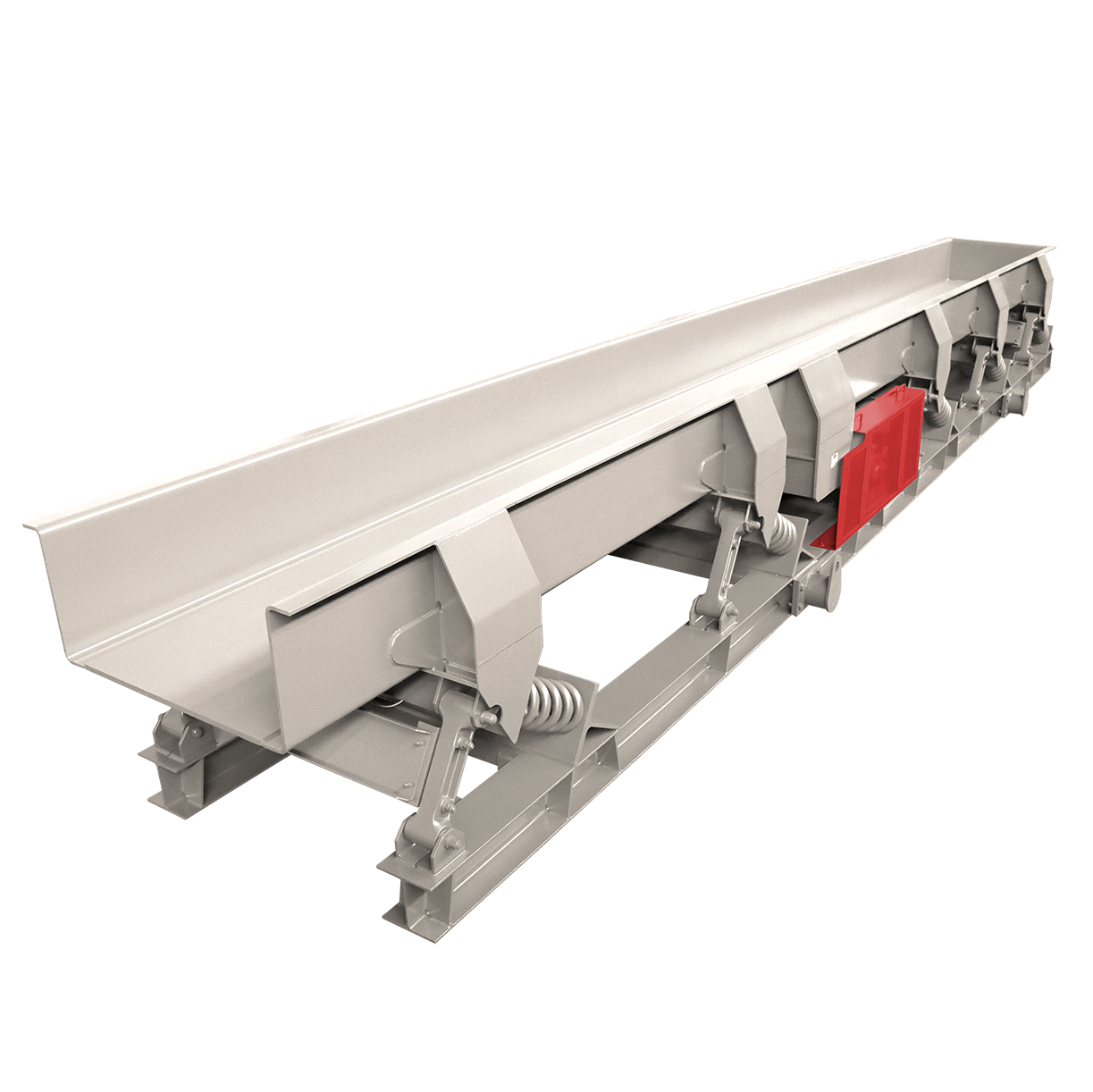

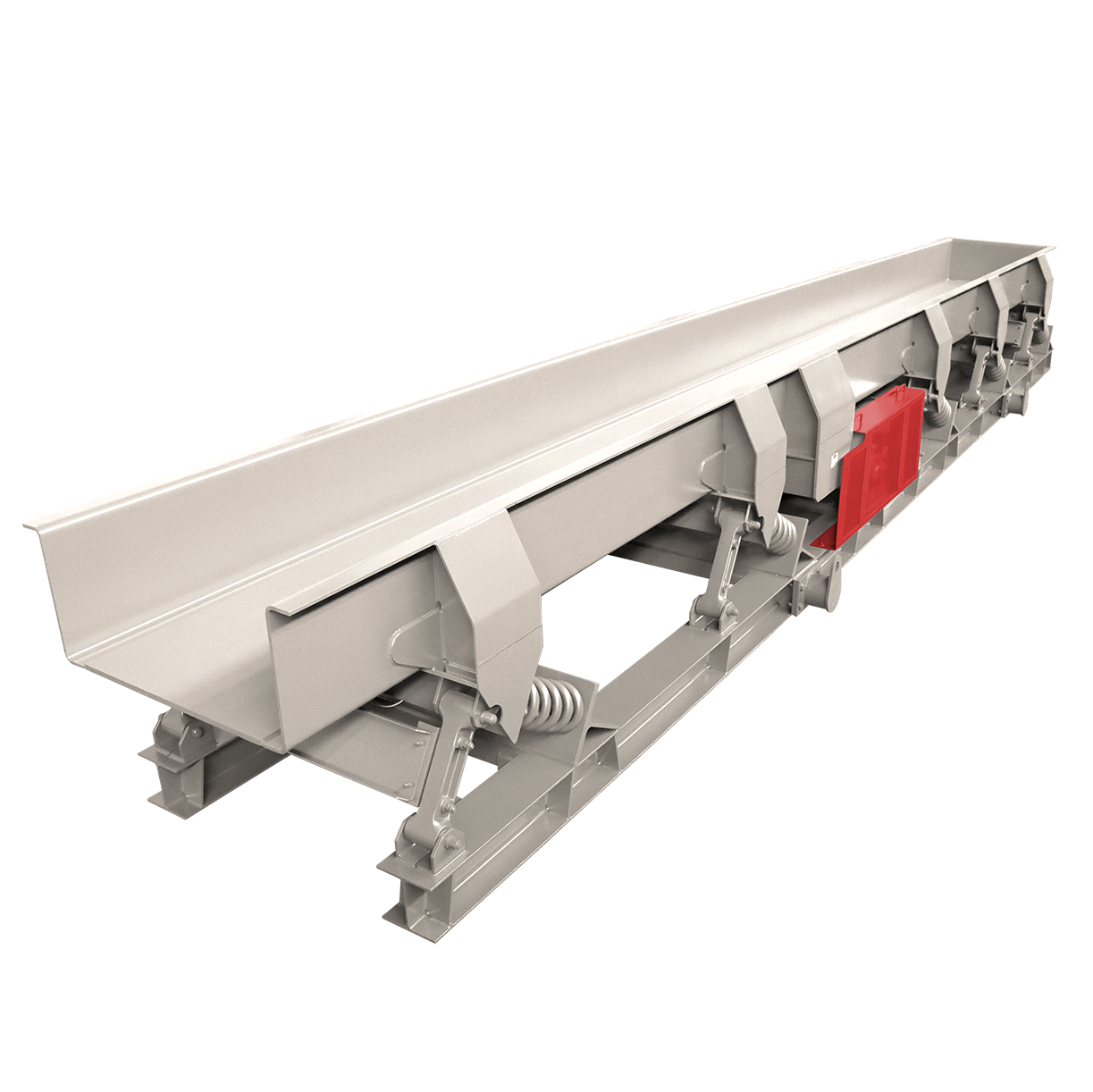

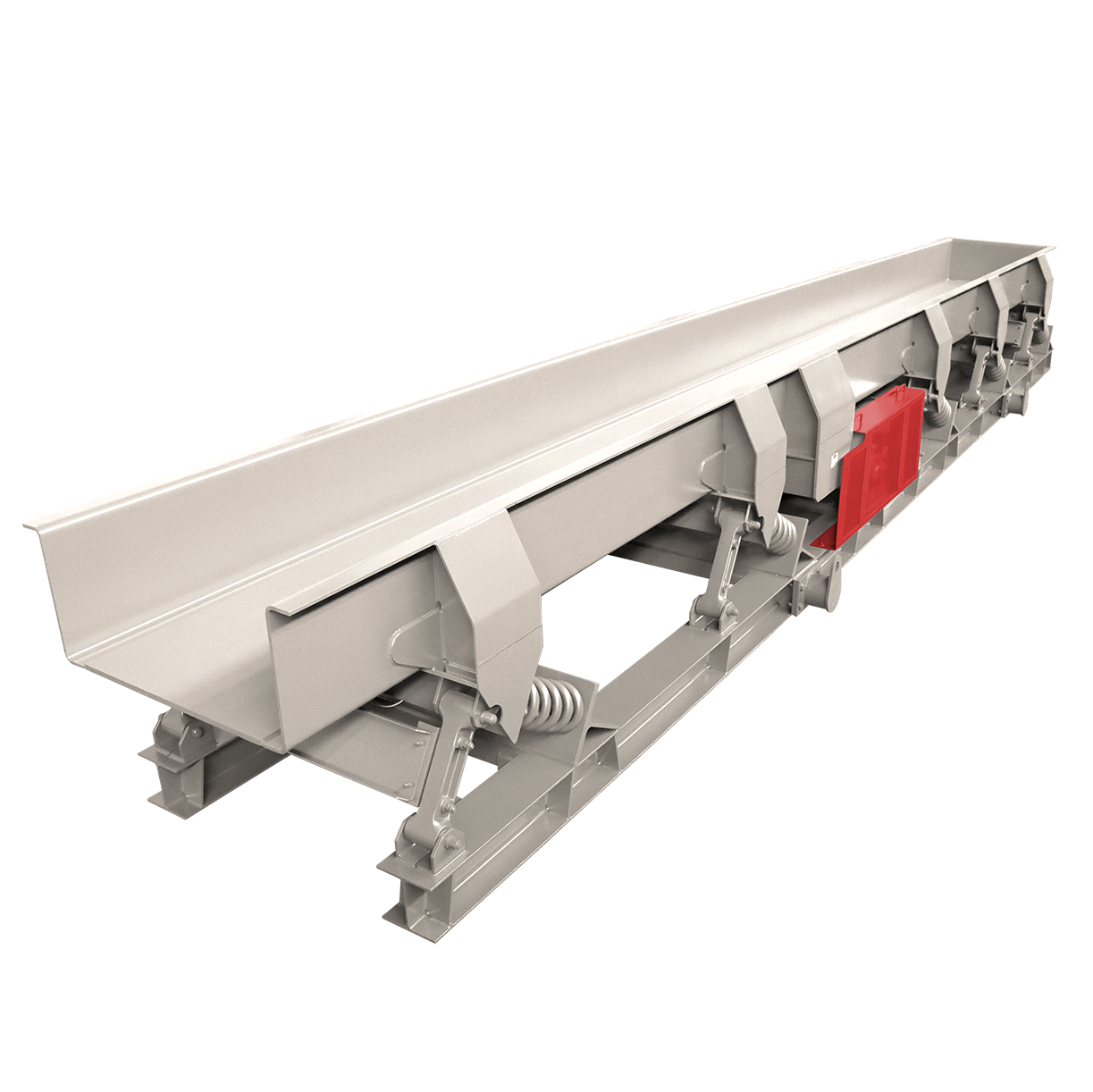

Carrier is the expert in vibrating technology used as a means to convey bulk material. Our units are suited for many industries: wood logs and chips, chemical powders, synthetic rubber, coal, sand and minerals, food products, waste and recycled materials, and many others. On a vibrating equipment, the conveying surface is made of a one-piece trough so that the product never comes in contact with the very few moving parts. This guarantees less product loss but also less potential damage on the unit and less downtime.

Providing the most efficient system to simultaneously convey and process a variety of products, our natural frequency conveyors minimize power and maintenance requirements. With such reliability, they are particularly suited for production units operating 24/7, as in chemical and petrochemical plants, sugar or wood factories, foundries,…

We are also the pioneer of natural frequency drive. The trough motion is initiated by the motor, then the spring assembly takes over and becomes the driving force, highly reducing energy consumption. Our designs can span to more than 30m with only one drive! The springs are evenly distributed along the length of the conveyor, for less stress and breakage.

We make the most of vibrating technology advantages by adding custom features. This can include:

- Abrasion-resistant liners or replaceable conveying surface

- Non-stick coating

- Radial and/or incline conveying

- Special sections for screening, sorting, dewatering, metal detection,…

- Bidirectional (two-way) conveying

- Hood for noise, heat, smoke and dust containment

We offer technical support, aftersales service and spare parts all around the world. And we are always available to talk about your application and find the best custom solution.

Vibrating Conveyors

Carrier is the reference in custom design and manufacturing of vibrating equipment for bulk material processing.

Our vibrating conveyors operate on natural frequency. They are the most reliable and energy-saving system to simultaneously convey and process solids, powders and other bulk products from every industry.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

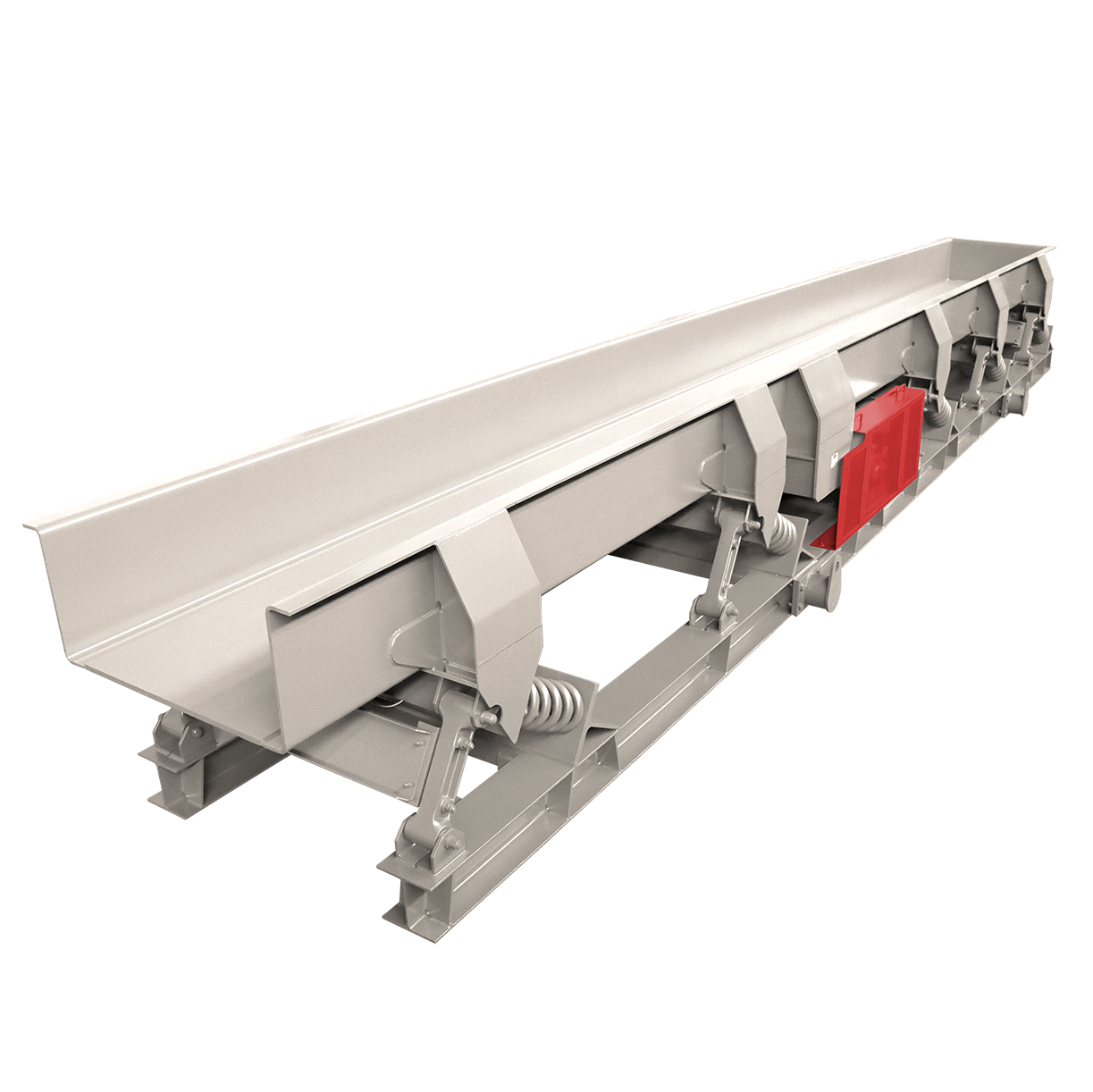

Carrier is the expert in vibrating technology used as a means to convey bulk material. Our units are suited for many industries: wood logs and chips, chemical powders, synthetic rubber, coal, sand and minerals, food products, waste and recycled materials, and many others. On a vibrating equipment, the conveying surface is made of a one-piece trough so that the product never comes in contact with the very few moving parts. This guarantees less product loss but also less potential damage on the unit and less downtime.

Providing the most efficient system to simultaneously convey and process a variety of products, our natural frequency conveyors minimize power and maintenance requirements. With such reliability, they are particularly suited for production units operating 24/7, as in chemical and petrochemical plants, sugar or wood factories, foundries,…

We are also the pioneer of natural frequency drive. The trough motion is initiated by the motor, then the spring assembly takes over and becomes the driving force, highly reducing energy consumption. Our designs can span to more than 30m with only one drive! The springs are evenly distributed along the length of the conveyor, for less stress and breakage.

We make the most of vibrating technology advantages by adding custom features. This can include:

- Abrasion-resistant liners or replaceable conveying surface

- Non-stick coating

- Radial and/or incline conveying

- Special sections for screening, sorting, dewatering, metal detection,…

- Bidirectional (two-way) conveying

- Hood for noise, heat, smoke and dust containment

We offer technical support, aftersales service and spare parts all around the world. And we are always available to talk about your application and find the best custom solution.

Vibrating Conveyors

Carrier is the reference in custom design and manufacturing of vibrating equipment for bulk material processing.

Our vibrating conveyors operate on natural frequency. They are the most reliable and energy-saving system to simultaneously convey and process solids, powders and other bulk products from every industry.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

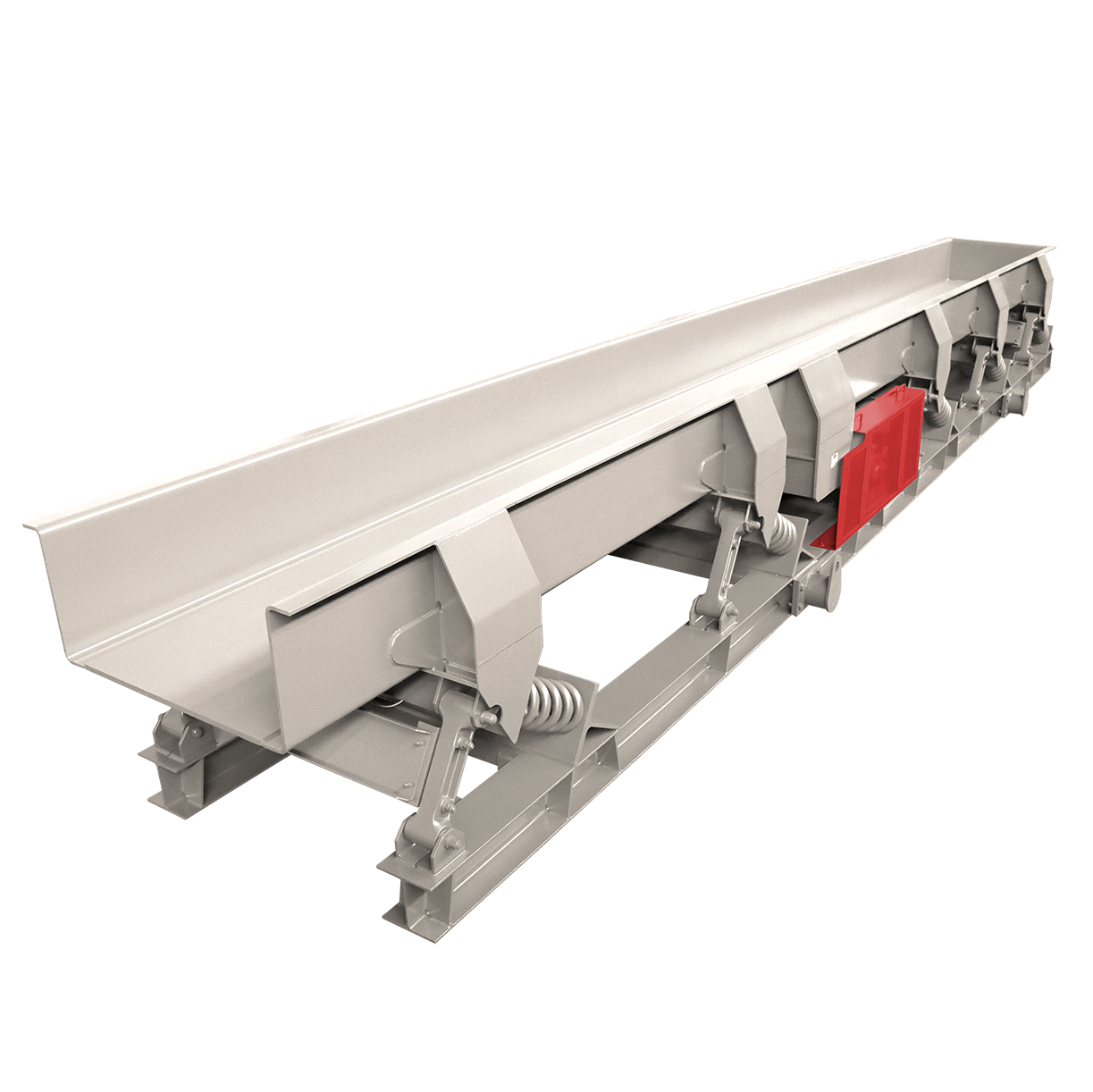

Carrier is the expert in vibrating technology used as a means to convey bulk material. Our units are suited for many industries: wood logs and chips, chemical powders, synthetic rubber, coal, sand and minerals, food products, waste and recycled materials, and many others. On a vibrating equipment, the conveying surface is made of a one-piece trough so that the product never comes in contact with the very few moving parts. This guarantees less product loss but also less potential damage on the unit and less downtime.

Providing the most efficient system to simultaneously convey and process a variety of products, our natural frequency conveyors minimize power and maintenance requirements. With such reliability, they are particularly suited for production units operating 24/7, as in chemical and petrochemical plants, sugar or wood factories, foundries,…

We are also the pioneer of natural frequency drive. The trough motion is initiated by the motor, then the spring assembly takes over and becomes the driving force, highly reducing energy consumption. Our designs can span to more than 30m with only one drive! The springs are evenly distributed along the length of the conveyor, for less stress and breakage.

We make the most of vibrating technology advantages by adding custom features. This can include:

- Abrasion-resistant liners or replaceable conveying surface

- Non-stick coating

- Radial and/or incline conveying

- Special sections for screening, sorting, dewatering, metal detection,…

- Bidirectional (two-way) conveying

- Hood for noise, heat, smoke and dust containment

We offer technical support, aftersales service and spare parts all around the world. And we are always available to talk about your application and find the best custom solution.

Vibrating Conveyors

Carrier is the reference in custom design and manufacturing of vibrating equipment for bulk material processing.

Our vibrating conveyors operate on natural frequency. They are the most reliable and energy-saving system to simultaneously convey and process solids, powders and other bulk products from every industry.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

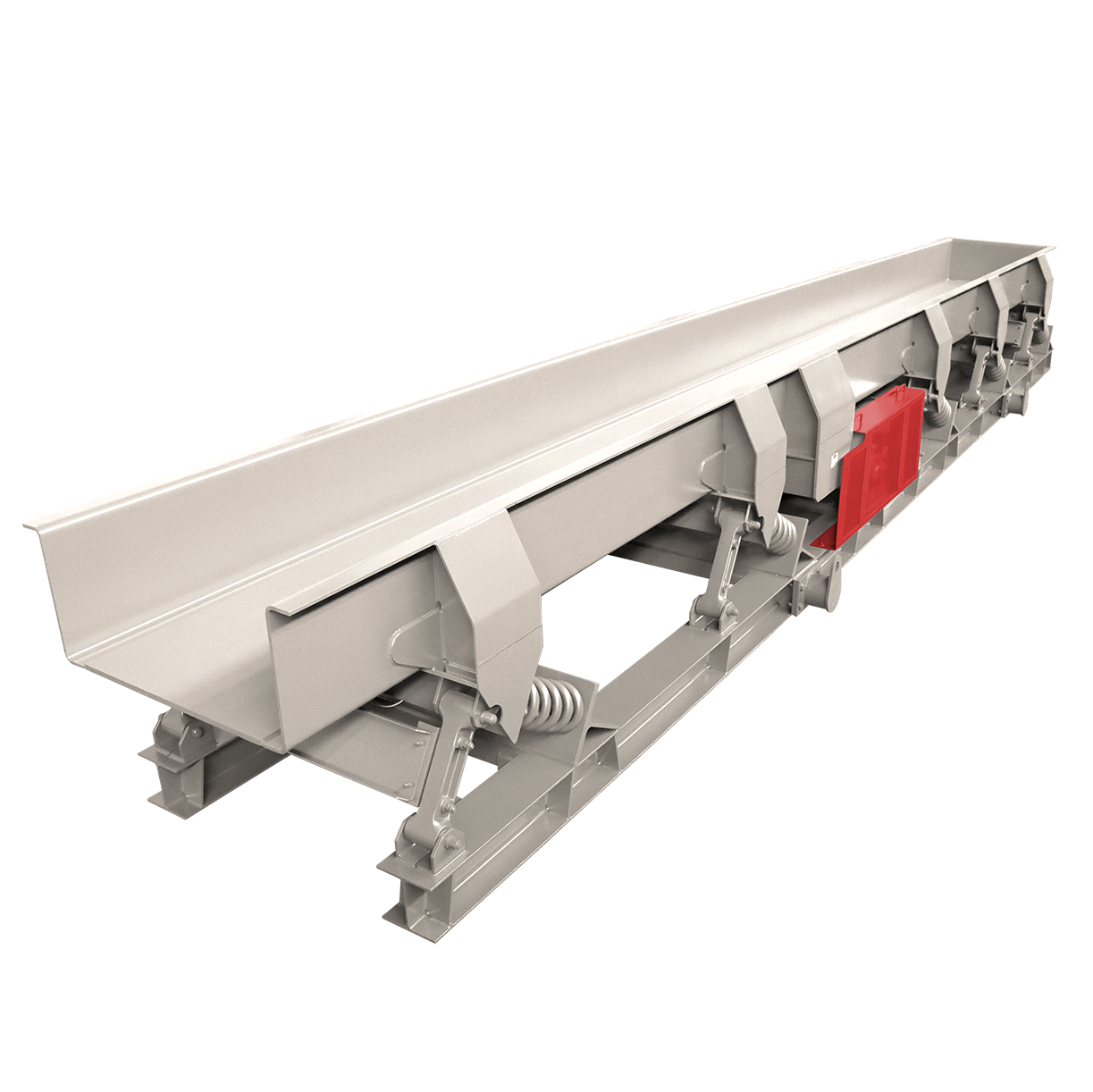

Carrier is the expert in vibrating technology used as a means to convey bulk material. Our units are suited for many industries: wood logs and chips, chemical powders, synthetic rubber, coal, sand and minerals, food products, waste and recycled materials, and many others. On a vibrating equipment, the conveying surface is made of a one-piece trough so that the product never comes in contact with the very few moving parts. This guarantees less product loss but also less potential damage on the unit and less downtime.

Providing the most efficient system to simultaneously convey and process a variety of products, our natural frequency conveyors minimize power and maintenance requirements. With such reliability, they are particularly suited for production units operating 24/7, as in chemical and petrochemical plants, sugar or wood factories, foundries,…

We are also the pioneer of natural frequency drive. The trough motion is initiated by the motor, then the spring assembly takes over and becomes the driving force, highly reducing energy consumption. Our designs can span to more than 30m with only one drive! The springs are evenly distributed along the length of the conveyor, for less stress and breakage.

We make the most of vibrating technology advantages by adding custom features. This can include:

- Abrasion-resistant liners or replaceable conveying surface

- Non-stick coating

- Radial and/or incline conveying

- Special sections for screening, sorting, dewatering, metal detection,…

- Bidirectional (two-way) conveying

- Hood for noise, heat, smoke and dust containment

We offer technical support, aftersales service and spare parts all around the world. And we are always available to talk about your application and find the best custom solution.

Vibrating Conveyors

Carrier is the reference in custom design and manufacturing of vibrating equipment for bulk material processing.

Our vibrating conveyors operate on natural frequency. They are the most reliable and energy-saving system to simultaneously convey and process solids, powders and other bulk products from every industry.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier is the expert in vibrating technology used as a means to convey bulk material. Our units are suited for many industries: wood logs and chips, chemical powders, synthetic rubber, coal, sand and minerals, food products, waste and recycled materials, and many others. On a vibrating equipment, the conveying surface is made of a one-piece trough so that the product never comes in contact with the very few moving parts. This guarantees less product loss but also less potential damage on the unit and less downtime.

Providing the most efficient system to simultaneously convey and process a variety of products, our natural frequency conveyors minimize power and maintenance requirements. With such reliability, they are particularly suited for production units operating 24/7, as in chemical and petrochemical plants, sugar or wood factories, foundries,…

We are also the pioneer of natural frequency drive. The trough motion is initiated by the motor, then the spring assembly takes over and becomes the driving force, highly reducing energy consumption. Our designs can span to more than 30m with only one drive! The springs are evenly distributed along the length of the conveyor, for less stress and breakage.

We make the most of vibrating technology advantages by adding custom features. This can include:

- Abrasion-resistant liners or replaceable conveying surface

- Non-stick coating

- Radial and/or incline conveying

- Special sections for screening, sorting, dewatering, metal detection,…

- Bidirectional (two-way) conveying

- Hood for noise, heat, smoke and dust containment

We offer technical support, aftersales service and spare parts all around the world. And we are always available to talk about your application and find the best custom solution.

Vibrating Conveyors

Carrier is the reference in custom design and manufacturing of vibrating equipment for bulk material processing.

Our vibrating conveyors operate on natural frequency. They are the most reliable and energy-saving system to simultaneously convey and process solids, powders and other bulk products from every industry.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier is the expert in vibrating technology used as a means to convey bulk material. Our units are suited for many industries: wood logs and chips, chemical powders, synthetic rubber, coal, sand and minerals, food products, waste and recycled materials, and many others. On a vibrating equipment, the conveying surface is made of a one-piece trough so that the product never comes in contact with the very few moving parts. This guarantees less product loss but also less potential damage on the unit and less downtime.

Providing the most efficient system to simultaneously convey and process a variety of products, our natural frequency conveyors minimize power and maintenance requirements. With such reliability, they are particularly suited for production units operating 24/7, as in chemical and petrochemical plants, sugar or wood factories, foundries,…

We are also the pioneer of natural frequency drive. The trough motion is initiated by the motor, then the spring assembly takes over and becomes the driving force, highly reducing energy consumption. Our designs can span to more than 30m with only one drive! The springs are evenly distributed along the length of the conveyor, for less stress and breakage.

We make the most of vibrating technology advantages by adding custom features. This can include:

- Abrasion-resistant liners or replaceable conveying surface

- Non-stick coating

- Radial and/or incline conveying

- Special sections for screening, sorting, dewatering, metal detection,…

- Bidirectional (two-way) conveying

- Hood for noise, heat, smoke and dust containment

We offer technical support, aftersales service and spare parts all around the world. And we are always available to talk about your application and find the best custom solution.

Vibrating Conveyors

Carrier is the reference in custom design and manufacturing of vibrating equipment for bulk material processing.

Our vibrating conveyors operate on natural frequency. They are the most reliable and energy-saving system to simultaneously convey and process solids, powders and other bulk products from every industry.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier is the expert in vibrating technology used as a means to convey bulk material. Our units are suited for many industries: wood logs and chips, chemical powders, synthetic rubber, coal, sand and minerals, food products, waste and recycled materials, and many others. On a vibrating equipment, the conveying surface is made of a one-piece trough so that the product never comes in contact with the very few moving parts. This guarantees less product loss but also less potential damage on the unit and less downtime.

Providing the most efficient system to simultaneously convey and process a variety of products, our natural frequency conveyors minimize power and maintenance requirements. With such reliability, they are particularly suited for production units operating 24/7, as in chemical and petrochemical plants, sugar or wood factories, foundries,…

We are also the pioneer of natural frequency drive. The trough motion is initiated by the motor, then the spring assembly takes over and becomes the driving force, highly reducing energy consumption. Our designs can span to more than 30m with only one drive! The springs are evenly distributed along the length of the conveyor, for less stress and breakage.

We make the most of vibrating technology advantages by adding custom features. This can include:

- Abrasion-resistant liners or replaceable conveying surface

- Non-stick coating

- Radial and/or incline conveying

- Special sections for screening, sorting, dewatering, metal detection,…

- Bidirectional (two-way) conveying

- Hood for noise, heat, smoke and dust containment

We offer technical support, aftersales service and spare parts all around the world. And we are always available to talk about your application and find the best custom solution.

Vibrating Conveyors

Carrier is the reference in custom design and manufacturing of vibrating equipment for bulk material processing.

Our vibrating conveyors operate on natural frequency. They are the most reliable and energy-saving system to simultaneously convey and process solids, powders and other bulk products from every industry.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Carrier is the expert in vibrating technology used as a means to convey bulk material. Our units are suited for many industries: wood logs and chips, chemical powders, synthetic rubber, coal, sand and minerals, food products, waste and recycled materials, and many others. On a vibrating equipment, the conveying surface is made of a one-piece trough so that the product never comes in contact with the very few moving parts. This guarantees less product loss but also less potential damage on the unit and less downtime.

Providing the most efficient system to simultaneously convey and process a variety of products, our natural frequency conveyors minimize power and maintenance requirements. With such reliability, they are particularly suited for production units operating 24/7, as in chemical and petrochemical plants, sugar or wood factories, foundries,…

We are also the pioneer of natural frequency drive. The trough motion is initiated by the motor, then the spring assembly takes over and becomes the driving force, highly reducing energy consumption. Our designs can span to more than 30m with only one drive! The springs are evenly distributed along the length of the conveyor, for less stress and breakage.

We make the most of vibrating technology advantages by adding custom features. This can include:

- Abrasion-resistant liners or replaceable conveying surface

- Non-stick coating

- Radial and/or incline conveying

- Special sections for screening, sorting, dewatering, metal detection,…

- Bidirectional (two-way) conveying

- Hood for noise, heat, smoke and dust containment

We offer technical support, aftersales service and spare parts all around the world. And we are always available to talk about your application and find the best custom solution.

A CUSTOM SOLUTION?