Vibrating Spiral Elevators

Carrier provide equipment relying on vibrating technology and custom-designed to adapt to your process and needs.

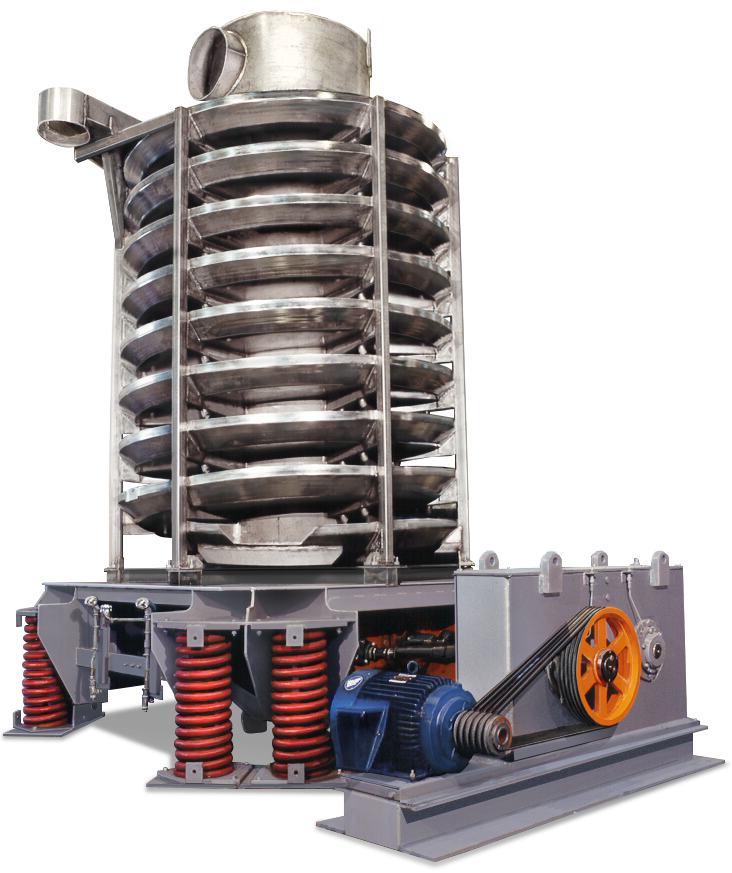

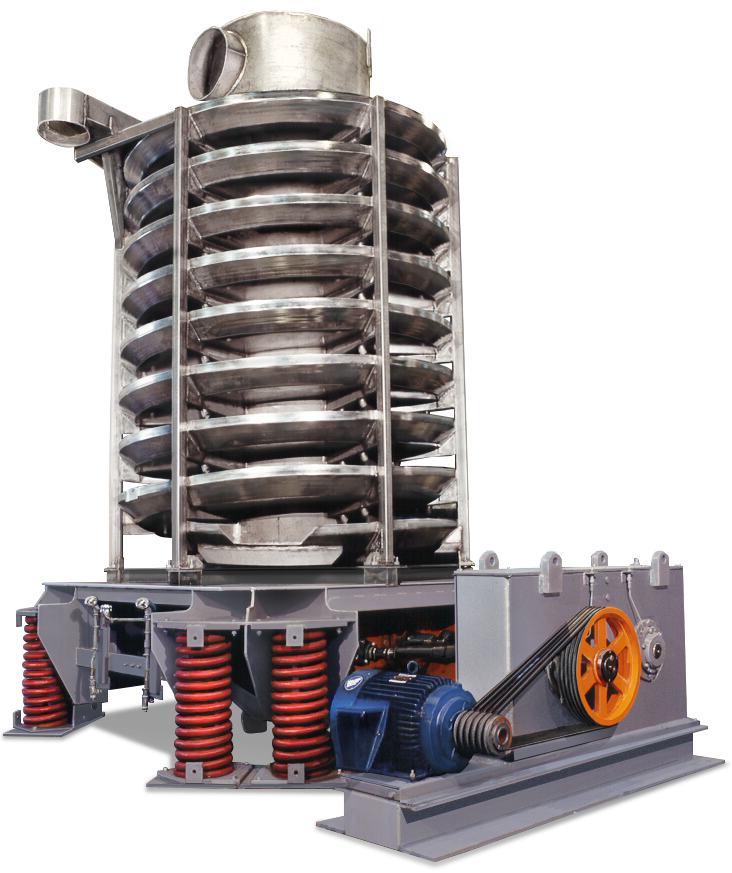

The spiral elevator is a unique equipment that conveys vertically while completing other thermal process. It provides a maximized retention time and a large processing area in exchange for a minimal footprint.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Some production lines need the material to be carried upwards at some point and the spiral elevator is the best answer to that concern. With a lift and twist motion, it gently pushes the product particles along the helicoidal deck circling around the central tower. This procures quite a large conveying and processing area compared to used floor space. Carrier spirals can rise up to several meters.

Like most of our equipment, spiral elevators can come with extra features to complete thermal process during the conveying of the bulk material (often powders, rubber crumbs or food products). This is achieved through the installation of jackets under and/or above the conveying deck. A processing gas or fluid is passed through these jackets to dry, heat or cool the product by indirect heat transfer. This makes the spiral elevator suited for many materials (sticky, fragile, explosive, hygroscopic, temperature-sensitive…)

Carrier vibrating spirals can be equipped with adjustable vibration parameters (angle of attack, stroke and frequency) to fully control the retention time of the product. This helps ensure that the particles undergo less degradation.

Carrier spiral elevators can benefit from our aftersales service, technical support and spare parts delivery all around the world. Learn what we do for our many customers.

Vibrating Spiral Elevators

Carrier provide equipment relying on vibrating technology and custom-designed to adapt to your process and needs.

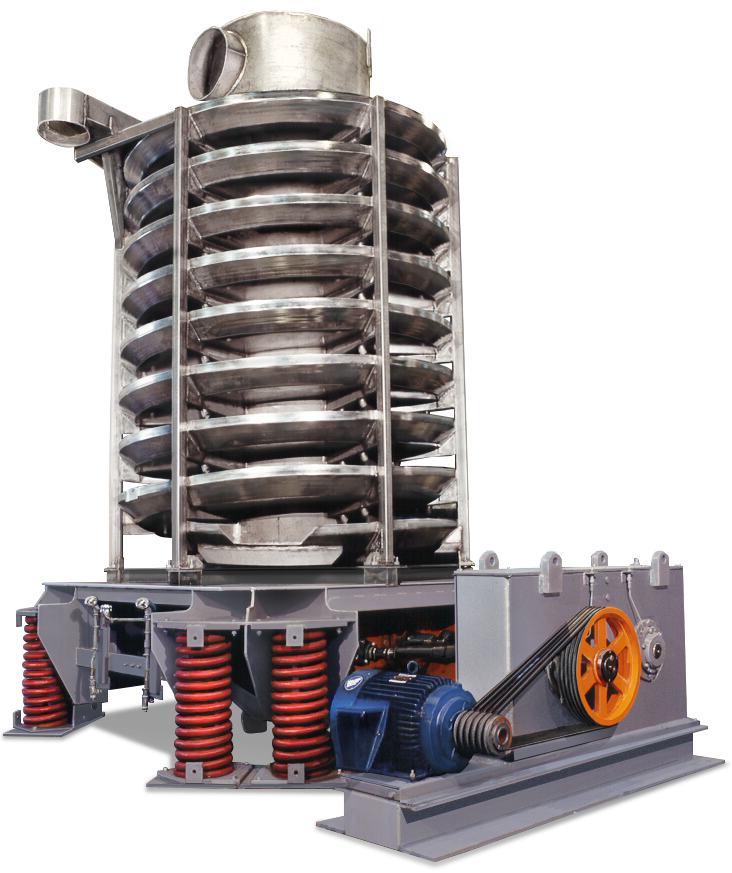

The spiral elevator is a unique equipment that conveys vertically while completing other thermal process. It provides a maximized retention time and a large processing area in exchange for a minimal footprint.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

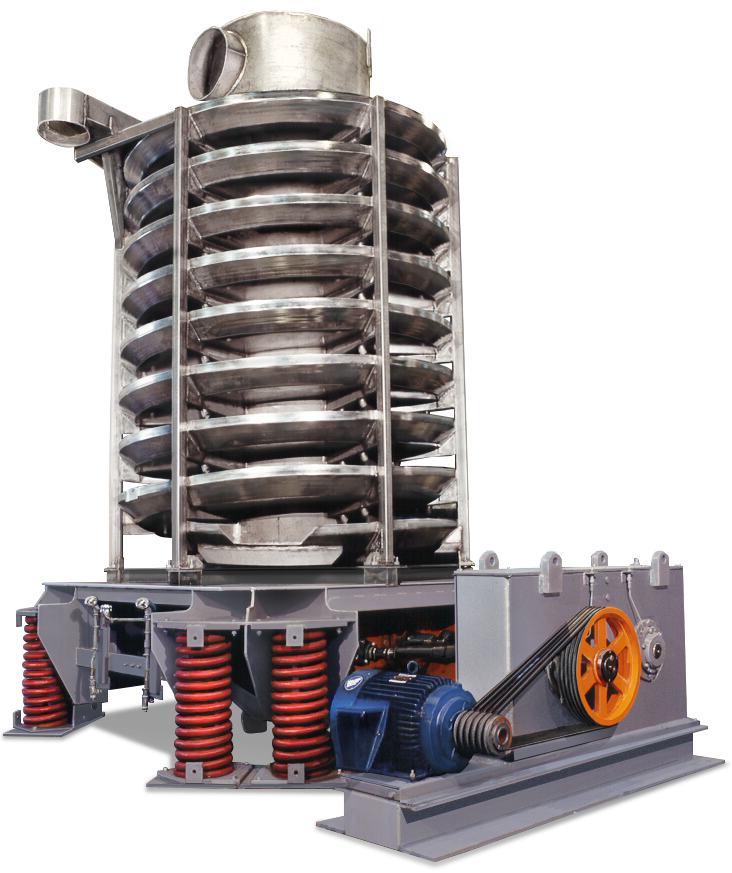

Some production lines need the material to be carried upwards at some point and the spiral elevator is the best answer to that concern. With a lift and twist motion, it gently pushes the product particles along the helicoidal deck circling around the central tower. This procures quite a large conveying and processing area compared to used floor space. Carrier spirals can rise up to several meters.

Like most of our equipment, spiral elevators can come with extra features to complete thermal process during the conveying of the bulk material (often powders, rubber crumbs or food products). This is achieved through the installation of jackets under and/or above the conveying deck. A processing gas or fluid is passed through these jackets to dry, heat or cool the product by indirect heat transfer. This makes the spiral elevator suited for many materials (sticky, fragile, explosive, hygroscopic, temperature-sensitive…)

Carrier vibrating spirals can be equipped with adjustable vibration parameters (angle of attack, stroke and frequency) to fully control the retention time of the product. This helps ensure that the particles undergo less degradation.

Carrier spiral elevators can benefit from our aftersales service, technical support and spare parts delivery all around the world. Learn what we do for our many customers.

Vibrating Spiral Elevators

Carrier provide equipment relying on vibrating technology and custom-designed to adapt to your process and needs.

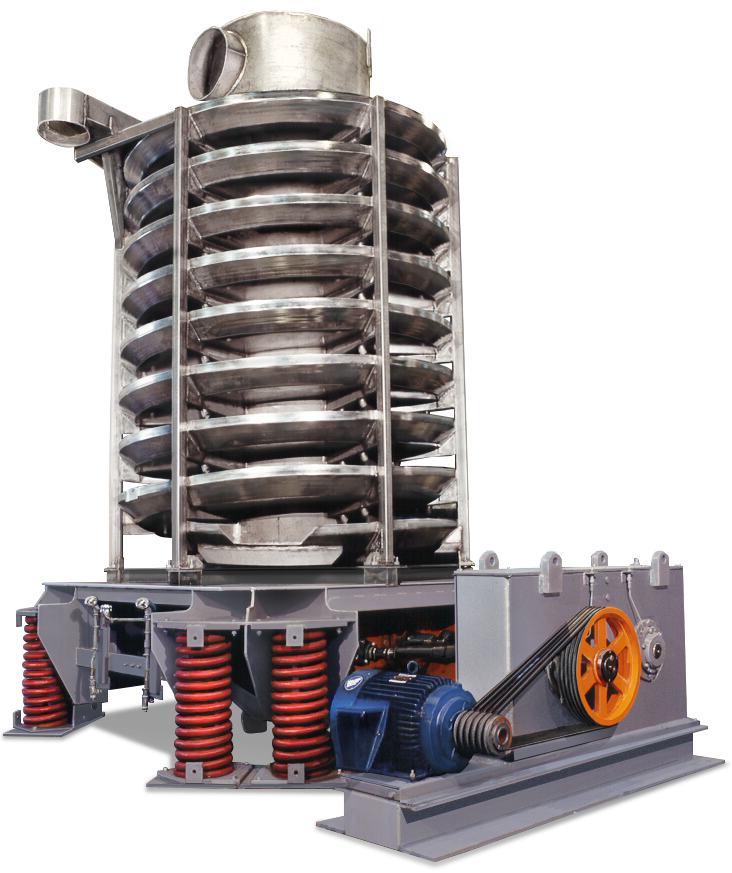

The spiral elevator is a unique equipment that conveys vertically while completing other thermal process. It provides a maximized retention time and a large processing area in exchange for a minimal footprint.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

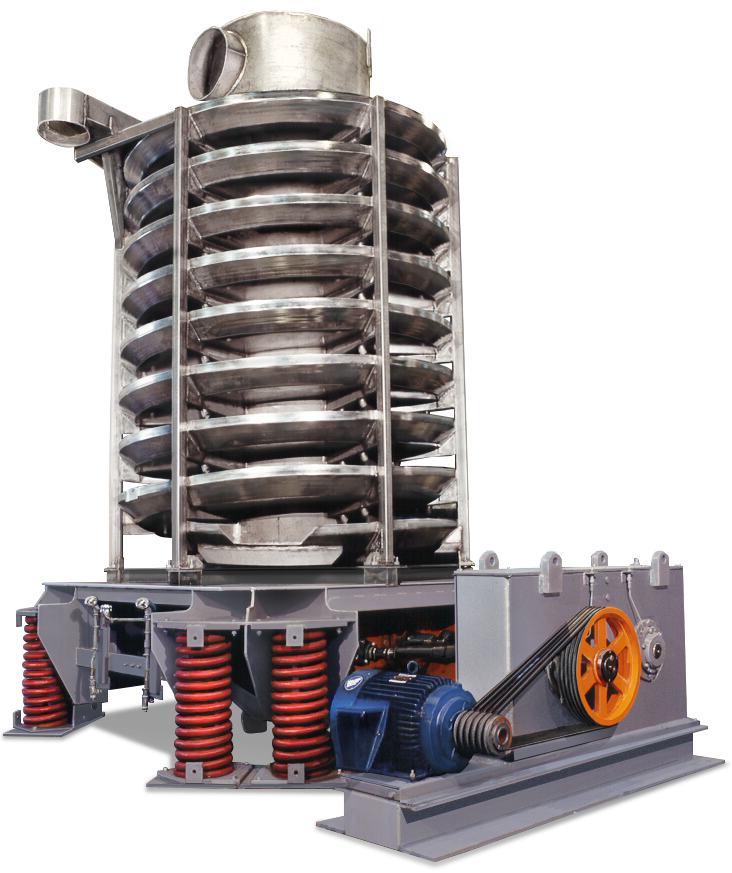

Some production lines need the material to be carried upwards at some point and the spiral elevator is the best answer to that concern. With a lift and twist motion, it gently pushes the product particles along the helicoidal deck circling around the central tower. This procures quite a large conveying and processing area compared to used floor space. Carrier spirals can rise up to several meters.

Like most of our equipment, spiral elevators can come with extra features to complete thermal process during the conveying of the bulk material (often powders, rubber crumbs or food products). This is achieved through the installation of jackets under and/or above the conveying deck. A processing gas or fluid is passed through these jackets to dry, heat or cool the product by indirect heat transfer. This makes the spiral elevator suited for many materials (sticky, fragile, explosive, hygroscopic, temperature-sensitive…)

Carrier vibrating spirals can be equipped with adjustable vibration parameters (angle of attack, stroke and frequency) to fully control the retention time of the product. This helps ensure that the particles undergo less degradation.

Carrier spiral elevators can benefit from our aftersales service, technical support and spare parts delivery all around the world. Learn what we do for our many customers.

Vibrating Spiral Elevators

Carrier provide equipment relying on vibrating technology and custom-designed to adapt to your process and needs.

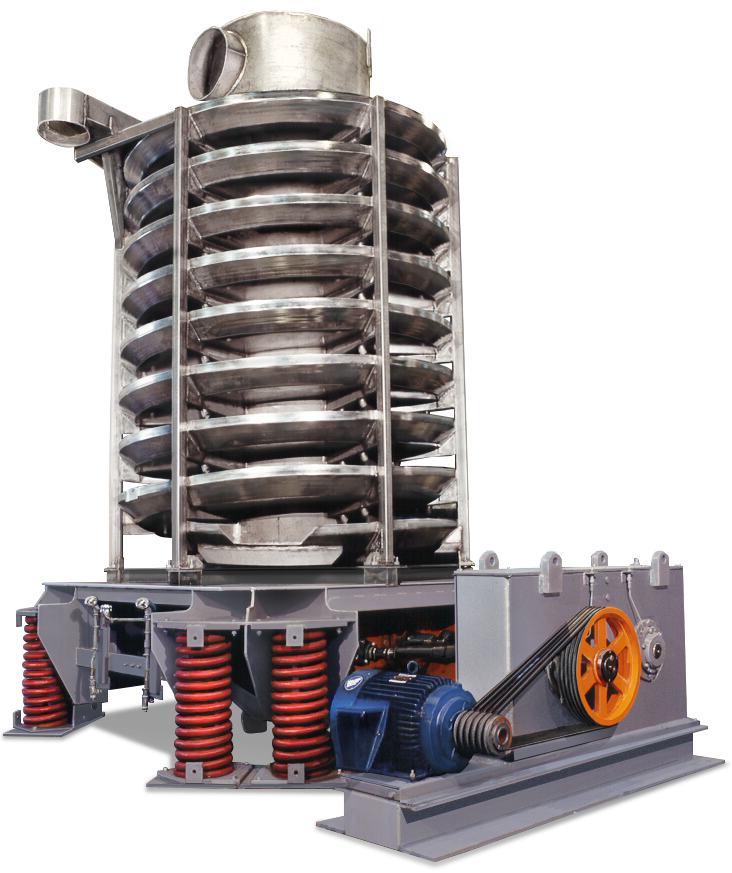

The spiral elevator is a unique equipment that conveys vertically while completing other thermal process. It provides a maximized retention time and a large processing area in exchange for a minimal footprint.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

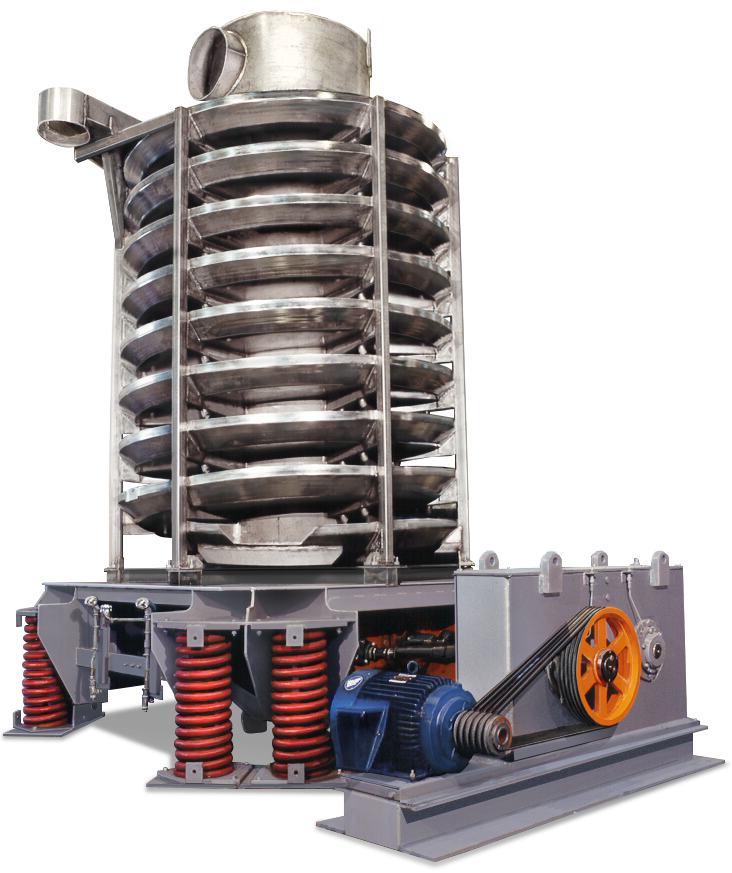

Some production lines need the material to be carried upwards at some point and the spiral elevator is the best answer to that concern. With a lift and twist motion, it gently pushes the product particles along the helicoidal deck circling around the central tower. This procures quite a large conveying and processing area compared to used floor space. Carrier spirals can rise up to several meters.

Like most of our equipment, spiral elevators can come with extra features to complete thermal process during the conveying of the bulk material (often powders, rubber crumbs or food products). This is achieved through the installation of jackets under and/or above the conveying deck. A processing gas or fluid is passed through these jackets to dry, heat or cool the product by indirect heat transfer. This makes the spiral elevator suited for many materials (sticky, fragile, explosive, hygroscopic, temperature-sensitive…)

Carrier vibrating spirals can be equipped with adjustable vibration parameters (angle of attack, stroke and frequency) to fully control the retention time of the product. This helps ensure that the particles undergo less degradation.

Carrier spiral elevators can benefit from our aftersales service, technical support and spare parts delivery all around the world. Learn what we do for our many customers.

Vibrating Spiral Elevators

Carrier provide equipment relying on vibrating technology and custom-designed to adapt to your process and needs.

The spiral elevator is a unique equipment that conveys vertically while completing other thermal process. It provides a maximized retention time and a large processing area in exchange for a minimal footprint.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Some production lines need the material to be carried upwards at some point and the spiral elevator is the best answer to that concern. With a lift and twist motion, it gently pushes the product particles along the helicoidal deck circling around the central tower. This procures quite a large conveying and processing area compared to used floor space. Carrier spirals can rise up to several meters.

Like most of our equipment, spiral elevators can come with extra features to complete thermal process during the conveying of the bulk material (often powders, rubber crumbs or food products). This is achieved through the installation of jackets under and/or above the conveying deck. A processing gas or fluid is passed through these jackets to dry, heat or cool the product by indirect heat transfer. This makes the spiral elevator suited for many materials (sticky, fragile, explosive, hygroscopic, temperature-sensitive…)

Carrier vibrating spirals can be equipped with adjustable vibration parameters (angle of attack, stroke and frequency) to fully control the retention time of the product. This helps ensure that the particles undergo less degradation.

Carrier spiral elevators can benefit from our aftersales service, technical support and spare parts delivery all around the world. Learn what we do for our many customers.

Vibrating Spiral Elevators

Carrier provide equipment relying on vibrating technology and custom-designed to adapt to your process and needs.

The spiral elevator is a unique equipment that conveys vertically while completing other thermal process. It provides a maximized retention time and a large processing area in exchange for a minimal footprint.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Some production lines need the material to be carried upwards at some point and the spiral elevator is the best answer to that concern. With a lift and twist motion, it gently pushes the product particles along the helicoidal deck circling around the central tower. This procures quite a large conveying and processing area compared to used floor space. Carrier spirals can rise up to several meters.

Like most of our equipment, spiral elevators can come with extra features to complete thermal process during the conveying of the bulk material (often powders, rubber crumbs or food products). This is achieved through the installation of jackets under and/or above the conveying deck. A processing gas or fluid is passed through these jackets to dry, heat or cool the product by indirect heat transfer. This makes the spiral elevator suited for many materials (sticky, fragile, explosive, hygroscopic, temperature-sensitive…)

Carrier vibrating spirals can be equipped with adjustable vibration parameters (angle of attack, stroke and frequency) to fully control the retention time of the product. This helps ensure that the particles undergo less degradation.

Carrier spiral elevators can benefit from our aftersales service, technical support and spare parts delivery all around the world. Learn what we do for our many customers.

Vibrating Spiral Elevators

Carrier provide equipment relying on vibrating technology and custom-designed to adapt to your process and needs.

The spiral elevator is a unique equipment that conveys vertically while completing other thermal process. It provides a maximized retention time and a large processing area in exchange for a minimal footprint.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Some production lines need the material to be carried upwards at some point and the spiral elevator is the best answer to that concern. With a lift and twist motion, it gently pushes the product particles along the helicoidal deck circling around the central tower. This procures quite a large conveying and processing area compared to used floor space. Carrier spirals can rise up to several meters.

Like most of our equipment, spiral elevators can come with extra features to complete thermal process during the conveying of the bulk material (often powders, rubber crumbs or food products). This is achieved through the installation of jackets under and/or above the conveying deck. A processing gas or fluid is passed through these jackets to dry, heat or cool the product by indirect heat transfer. This makes the spiral elevator suited for many materials (sticky, fragile, explosive, hygroscopic, temperature-sensitive…)

Carrier vibrating spirals can be equipped with adjustable vibration parameters (angle of attack, stroke and frequency) to fully control the retention time of the product. This helps ensure that the particles undergo less degradation.

Carrier spiral elevators can benefit from our aftersales service, technical support and spare parts delivery all around the world. Learn what we do for our many customers.

Vibrating Spiral Elevators

Carrier provide equipment relying on vibrating technology and custom-designed to adapt to your process and needs.

The spiral elevator is a unique equipment that conveys vertically while completing other thermal process. It provides a maximized retention time and a large processing area in exchange for a minimal footprint.

Carrier Europe serves EMEA (Europe – Middle-East – Africa). You are not located in EMEA ? Go to our other website.

Some production lines need the material to be carried upwards at some point and the spiral elevator is the best answer to that concern. With a lift and twist motion, it gently pushes the product particles along the helicoidal deck circling around the central tower. This procures quite a large conveying and processing area compared to used floor space. Carrier spirals can rise up to several meters.

Like most of our equipment, spiral elevators can come with extra features to complete thermal process during the conveying of the bulk material (often powders, rubber crumbs or food products). This is achieved through the installation of jackets under and/or above the conveying deck. A processing gas or fluid is passed through these jackets to dry, heat or cool the product by indirect heat transfer. This makes the spiral elevator suited for many materials (sticky, fragile, explosive, hygroscopic, temperature-sensitive…)

Carrier vibrating spirals can be equipped with adjustable vibration parameters (angle of attack, stroke and frequency) to fully control the retention time of the product. This helps ensure that the particles undergo less degradation.

Carrier spiral elevators can benefit from our aftersales service, technical support and spare parts delivery all around the world. Learn what we do for our many customers.

A CUSTOM SOLUTION?