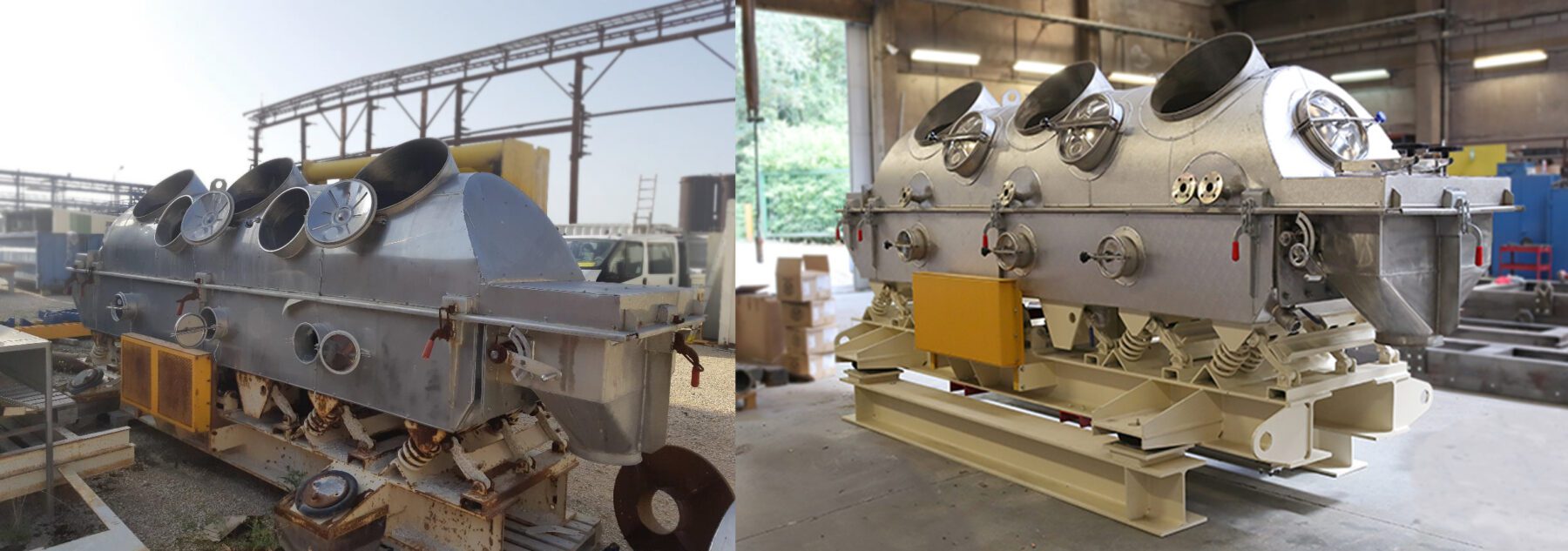

A dryer, abandoned outside during 10 years, has been resurrected by the Carrier Europe team.

This fluid bed dryer is a specific type of natural frequency equipment. It was delivered by Carrier in 2001 to the chemical industry. Due to production changes, it was sent off and stored outside, facing the rain, the sunshine, and the ravages of time.

Last year, the owner opened a new production line and asked our team if it would make sense to re-use this equipment. After a detailed study, we came to the conclusion that upgrading the dryer would lead to a cost saving of 60% compared to producing a whole new unit !

The complete overhaul consisted of:

-Repatriation in our workshop

-Detailed study, including new drawings & thermal exchange capacity

-Replacement of frame, springs, controls, thermal insulation, clamping

-Installation of a door in the hood

-Modification of the drain

-Installation of a ball valve

-Replacement of carbon steel parts by stainless steel parts

-Revision of the seal

-Delivery on site

Of course, this « as good as new » dryer and its capacity are fully guaranteed by Carrier Europe !

If you own a time-worn Carrier equipment, consider restoring it before replacing it with a new one !