Carrier's exclusive Delta Phase® drive system

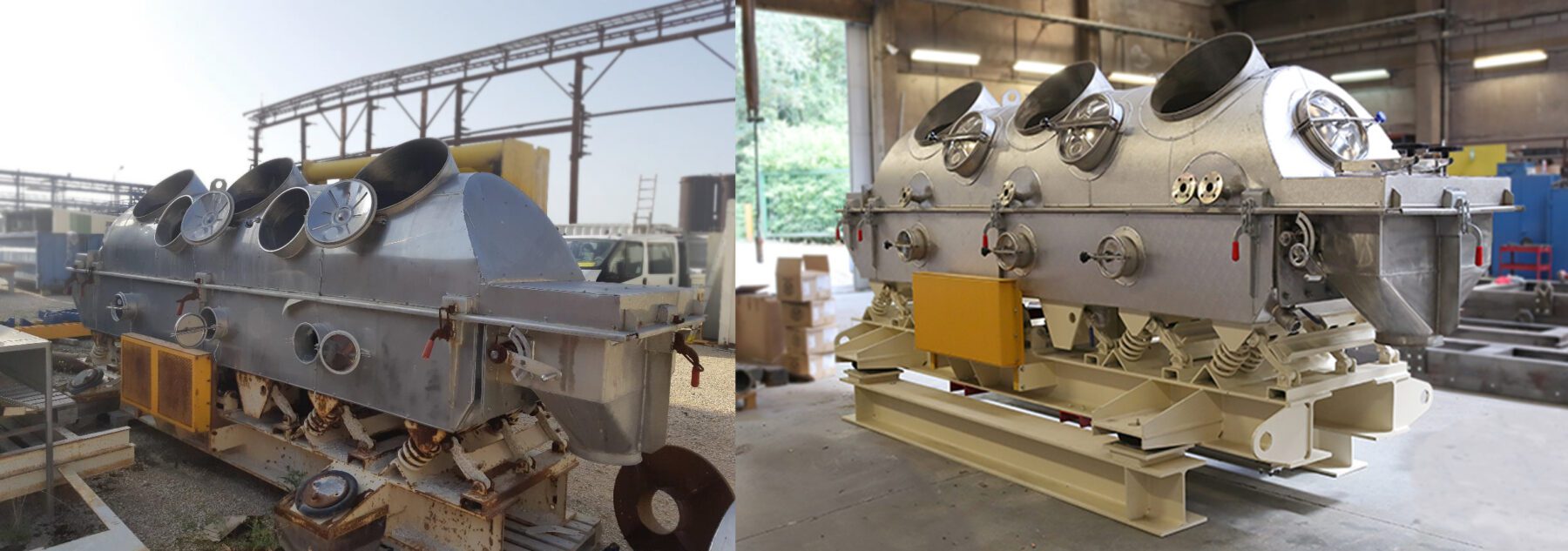

For more than 25 years, our Delta-Phase drive system has been the best friend of our customers in the process industry.

One of the most common problems when processing bulk material resides in its retention time: too short and you get an unfinished product strolling along your line; too long and you risk a loss of output as well as potential damage to the equipment and the product. But what if you could change your unit’s operating parameters to vary retention time depending on your current specific needs?

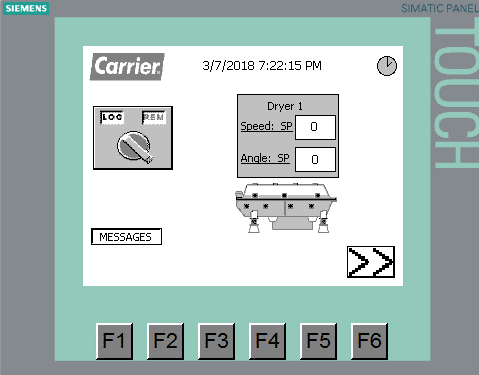

No device does that better than Carrier’s Delta Phase® drive : an electronic shaft synchronization system run by a programmable logic controller (PLC). This quality of life tool varies the angle of vibration “on the fly” to sequence and manage the product onward motion and speed, or even have it stationary. Needless to say, it gives you total control over your retention time. Moreover, this controller can hold up many “recipes”, each with its own sequence, corresponding to a specific production.

One of the main uses for this system is with shakeouts for the foundry industry, where retention time on the deck is accurately defined to prevent casting damage and maximize output. Since VFD (Variable frequency Drive) on the motor are required, we can also change the RPM “on the fly”. This has a direct impact on the G-forces and gives an additional possibility to influence the retention time. Increased G-forces can also be helpful to deal with viscous products.

For this reason, the Delta Phase is very popular with our fluid bed systems and with customers running different grades or types of products on the same line.