Customer service

AFTER SALES & SPARE PARTS

Installing your new equipment is not the end of our job! Not only do we offer robust and long-lasting equipment, we also make sure they keep running at full efficiency for a long time. With each installed machine you get a list of all the spare parts required on site for 2 years of hassle free operation. We also store all common and standard parts in our 800m² warehouse in Belgium, ensuring a quick delivery.

TECHNICAL SUPPORT

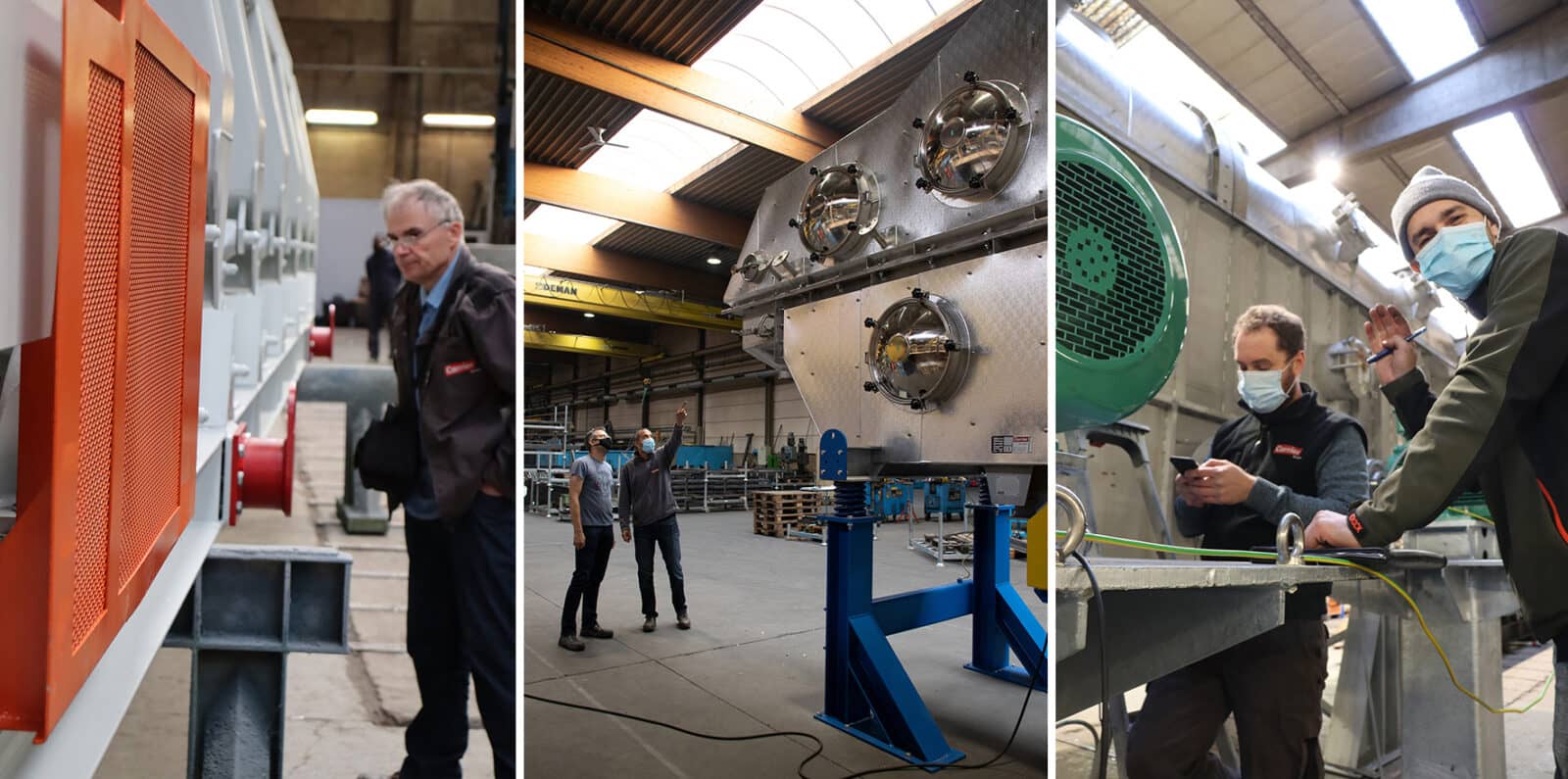

To help you get the best of your newly-acquired machine, we provide customer service with reactive but also preventive maintenance and recommendations for optimal and long-term operation. And when something goes wrong, our field service technicians are ready to travel to your site on short notice, with top priority assistance in less than 24h!

When appropriate, we can also assist you remotely with smartglasses.

We also propose annual maintenance contracts to manage regular technical interventions. This way you assure the best possible uptime of your equipment.

FREQUENTLY ASKED QUESTIONS

No. Except the noise coming from the vibration of the product itself, your machine must run in a smooth way, without significant noise, especially metallic noise.

If you hear abnormal noise, you must stop the machine as soon as possible and identify the cause. The cause can be loose fastener, impact with surrounding structures, worn part or structural cracks.

Contact Carrier in case of any doubt.

Contact our service team (service@carriereurope.be or +32 67 40 01 30). We will be pleased to help you.

The general drawing of your machine and/or its manual indicates the minimum recommended distance between the vibrating parts and surrounding structures/equipment. Generally, we recommend a minimum distance of 50 mm but some machine types may require more. For example, spiral elevators generally ask for a minimum distance of 100 mm.

Vibrating machines are sensitive to the vibrating weight. Any change in the vibrating weight can have significative impact on the vibration stroke and, so, the structural stress.

Always contact Carrier before any modification.

For a good follow-up of your machine, you must monitor the following parameters: stroke, speed, angle of attack (only for machine equipped with angle adjustment features), bearings temperature and motor amps.

All these parameters can be measured separately with specific instrument but Carrier has developed a tool for measuring easily the stroke, speed and angle of vibration through a smartphone app: VibraTrac 5.

See the following video for a demonstration: How to use Carrier VibraTrac

Carrier is keeping in stock all the spare parts common to a type of machine like springs, stabilizers and bearings. All the specific parts of your machine like drive shafts are only manufactured on request.

Standard delivery time for stock item is around one week.

If a technician is available, he can be on your site quickly depending on the travel time. Unfortunately, our technician team is limited and we cannot always guarantee immediate intervention. So we recommend to book a technician visit at least one month before the date.

In case of emergency, if no technicians are available, we still have the possibility to assist you remotely by phone, by Teams or by sending you smart glasses for real time assistance.

Carrier must study and validate any modification, but generally, it is possible.

Your machine manual includes a standard maintenance schedule, but Carrier can help you to define a specific schedule depending of your own maintenance constraints.

Before Carrier Europe was established in 1995, Locker built Carrier equipment under Carrier license. Carrier has taken over this part of Locker business many years ago.

We keep all the files for these machines (including drawings, design data and parts references) in our archives. We also keep parts in stock and can provide you with technical support. Do not hesitate to call our aftersales service.