Published in Glass International, June 2023

Vibrating fluid bed

Glass cullet recycling is a long process, requiring several stages: washing, initial sorting, drying for moisture decrease, optical sorting, elimination of fine particles, etc. All those stages generate energy and water consumption.

The basic principle of a vibrating equipment is the following: the product is conveyed on a one-piece trough, moving in an inclined motion, following a straight line. This motion creates successive tosses, as if the product was ‘jumping’ forward.

In a fluid bed, the trough is a perforated plate crossed by an air flow (hot or cold). The combination of this air flow and the solid particles of the product behaves like a boiling fluid (called fluidisation).

With the vibration, the mixed particles are constantly surrounded by the air flow, increasing thermal efficiency. This is why vibrating fluid beds are very effective and efficient for heating, drying or cooling bulk materials. The whole unit is hooded for better atmosphere containment.

Installation

The installation of a vibrating fluid bed dryer/cooler includes auxiliary accessories such as fans, a burner or heat exchanger, ducting, filtration systems, a control panel, etc. This equipment process area is split in two zones to complete two consecutive processes: first hot air removes the surface moisture of the product and then cold air cools it down to the desired output temperature. Being able to dry and cool in a single unit can significantly reduce the equipment footprint compared to other drying and cooling equipment.

Advantages

As previously mentioned, the first advantage of the vibrating fluid bed is the thermal efficiency, due to the maximised contact surface of the product with the process air. Other advantages include the constant mixing of the product, promoting a uniform thermal exposure for a more controlled heat process, the low particle degradation thanks to pinpoint calculated vibrating parameters and the fact that no moving parts of the equipment are in contact with the product. This also means less maintenance and downtime.

Speaking of vibration parameters, Carrier was the first to develop and patent an electronic drive system which allows to change the angle of attack with the push of a button. The angle of attack determines the retention time of the product in the fluid bed. This is very useful when different product grades are processed on the same machine. Preset parameters can then be used to guarantee constant product quality for each product grade.

Equipment such as this has been installed in the glass industry. A few years ago, we installed such a vibrating fluid bed system at one of the main glass waste recyclers. The machine processes about 15 t/h of glass cullet. Most glass cullets contain a bacterial load from food rests. The high temperature of the air will kill all organisms, the vibration and fluidization will clean the cullets touching each other as they travel forward in the fluid bed and the fine particles during the drying process are extracted from the hood of the fluid bed towards filtration systems. The clean cullets at the end will go through a short cooling section before leaving the fluid bed. This is to date the most compact and environmentally friendly method to clean waste glass.

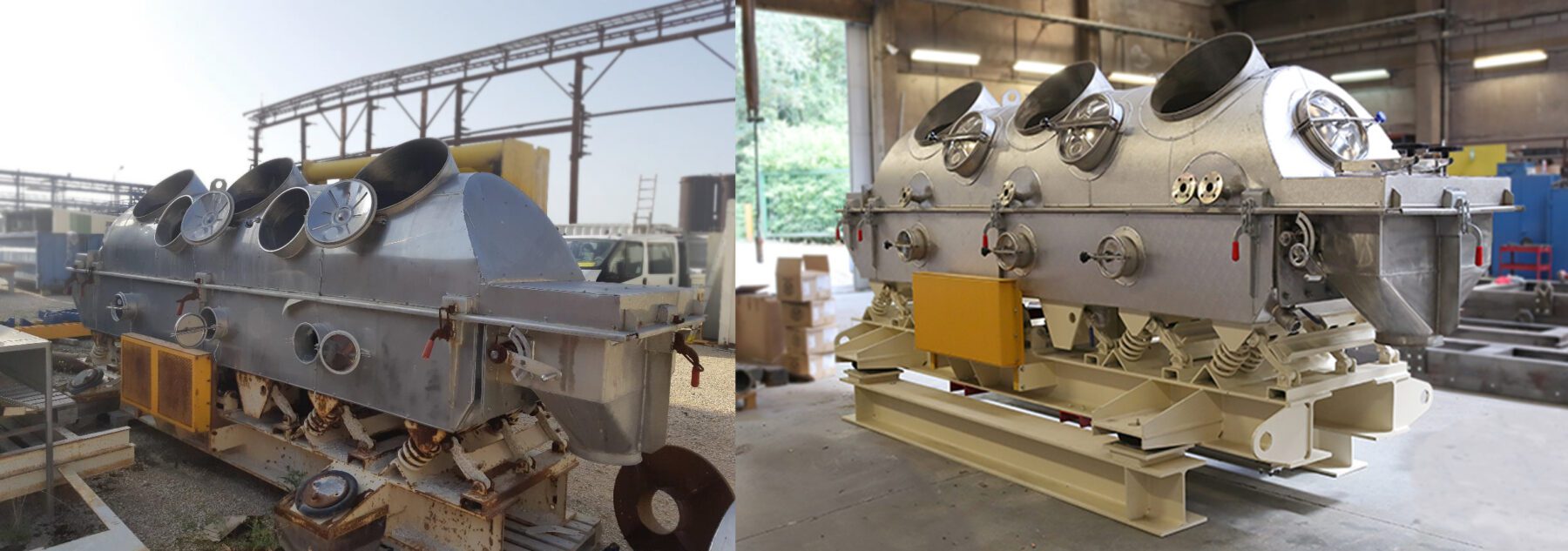

Glass cullet before and after drying in a fluid bed.

Custom design

Each product, process and customer location have their specifics. The most appropriate equipment will therefore be custom designed. Besides eventual building constraints the size of the equipment will be defined by the process parameters. To establish the most efficient parameters we propose our customers to run tests in our lab with samples. Once we obtain the sweet spot parameters we can determine the exact size of the required equipment for a certain capacity and give a process guarantee to the customer. Carrier’s decades of experience and knowledge will also make sure that the proposed equipment will last for many years to come.

Applications

- Applications for the glass industry include:

In the fiberglass production, a fluid bed system with 3 process sections for drying, curing, and cooling. - Also in fiberglass production, conveyors with special protection against corrosion when eliminating “cellar waste”. Also downstream, during the curing process. In both cases, a conventional, non-vibrating, conveyor wouldn’t be suitable.

- For glass containers, a dedicated quenching device can help with the elimination of “bad gobs”.

- For all glass sectors, conveyors with extra wearing resistance can find a place in the cullet return circuits or below the furnace, when draining the furnace during a general cold repair.

Carrier Europe equipment is also used for handling raw materials. Our vibrating fluid bed dryer/cooler is perfectly suited for silica sand processing. More generally, our equipment is convenient for some parts of batch plants, from storage in warehouses to furnace feeders.

Global outlook

Glass and fiberglass have always been important markets for Carrier Europe, but there are other markets where we are well established such as rubber, wood, chemicals, food, foundry, recycling – in fact, in every industry processing solids. Depending on the trends in these different markets, glass/fiberglass can represent from 5% to 15% of our yearly business. It is also important to point out that we provide aftersales services everywhere on the globe to maintain and upgrade our machines. This is even more relevant now that we are observing a general trend to take better care of the installed equipment and perform maintenance or replace parts, rather than outright buying a whole new unit.

The industrial world is gradually shifting, particularly in Europe, and we are witnessing an increasing number of demands for applications related to recycling or saving of energy and resources. We are sure that, as a highly energy efficient technology, vibrating equipment will remain a big player in this context.