A unique type of shakeout

Carrier is known for custom designed, robust and reliable equipment. A perfect match with the foundry industry where operating conditions are amongst the most demanding of all industries we serve.

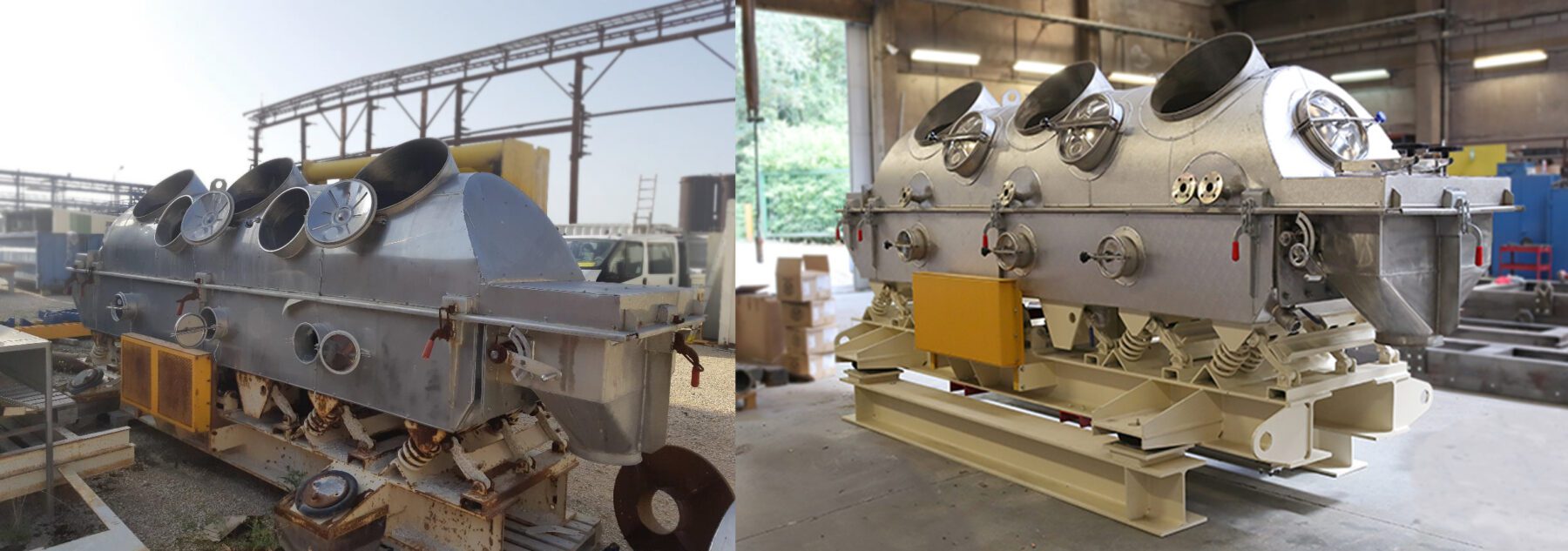

When one of our foundry customers asked us to quote for a replacement of an existing drum shake-out we proposed the Barrel Horse™. This customer serves the automotive industry and had too high losses due to damaged castings and was confronted with high maintenance costs. The rotating drum caused castings to fall down on each other and the bearing replacements, alignment issues and wear inside the drum were causing too many production stops.

The Barrel Horse took care of both these issues. Although it looks like a drum, it is not rotating. A three-dimensional elliptical motion is applied by gentle vibration resulting in a positive conveying action. This allows for horizontal or even inclined (uphill) positioning of the Barrel Horse. The dynamic forces are isolated allowing for minimal support requirements in the foundation.

When the molds enter the Barrel Horse they get submerged in sand and soon the castings start to swim in the sand bed. These agitation and mixing actions are cleaning the castings and at the same time reducing the sand lumps in size.

The gentle elliptical motion protects the casting quality and provides an excellent heat transfer. An optional water addition system, which was chosen by this customer, wets the sand via the side wall and allows for an indirect and controlled additional cooling process of the castings. When the sand leaves the Barrel Horse, it is slightly wet, low in temperature and homogenous. Ideal conditions to start recycling the sand.

The installation has been running continuously for 6 years and the customer reported a on a year base 3.000 tons less damaged castings compared to the set up with the rotary shake-out. Except for one anticipated replacement of the Hardox liners inside the Barrel Horse, no other significant maintenance or spart part costs occurred.